views

- Put on non-flammable gear and clear all dirt, oil, and grease from the area, then clamp the piece to be brazed and use a brush to apply an all-purpose flux.

- Heat the repaired area with a propane or acetylene torch, and apply the filler metal with a brazing rod.

- Remove the flux with hot water and polish the area with emery cloth once cooled; finish by applying a rust-resistant coating.

Wear non-flammable clothing, gloves, and safety goggles before you begin the brazing process.

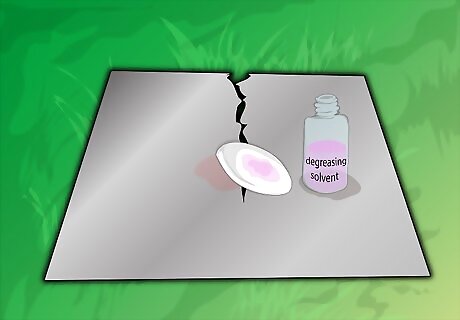

Clean all dirt, oil, paint, or other residue from the area to be repaired by aluminum brazing. Use a degreasing solvent to get rid of oil and grease. Depending on the size of the repaired area, you may need to sandblast the area or use an emery cloth, grinding wheel, or file.

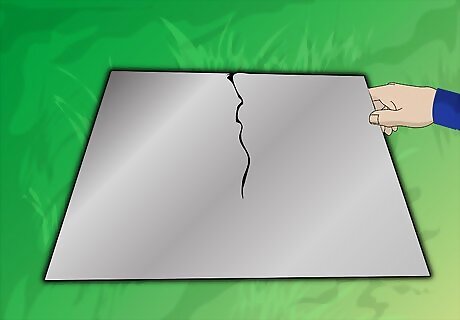

Clamp or support the piece to be brazed.

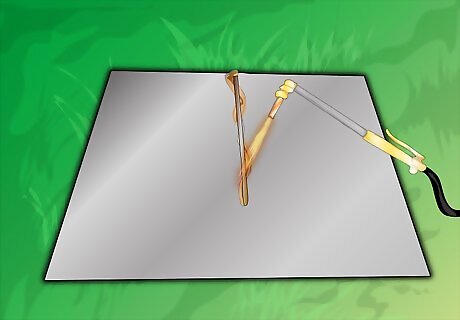

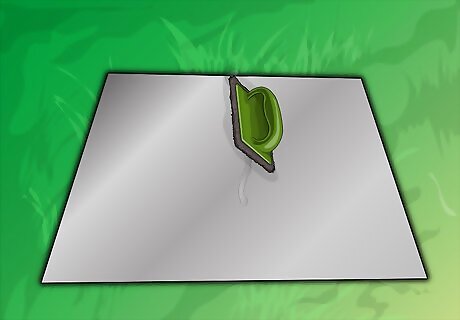

Use a brush to apply the flux appropriate to the temperatures and the metal. An all-purpose flux covers a wide range of temperatures and is beneficial to have on hand for general purpose brazing. Add flux by dipping the filler rod into the flux. You may also use flux-coated rods to eliminate this step. The flux-coated rods apply the flux during the aluminum brazing process.

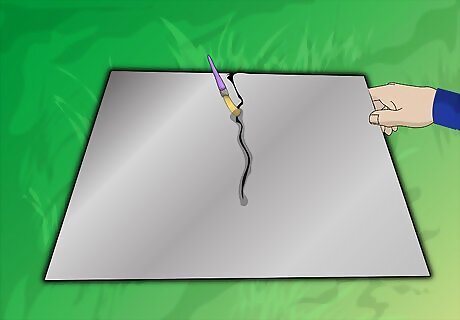

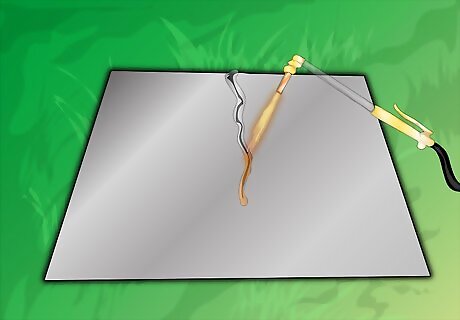

Heat the repaired area with a propane or acetylene torch until the aluminum shows an orange bloom. This happens when the metal gets very hot. Once you apply a flux, it should change colors or turn clear throughout.

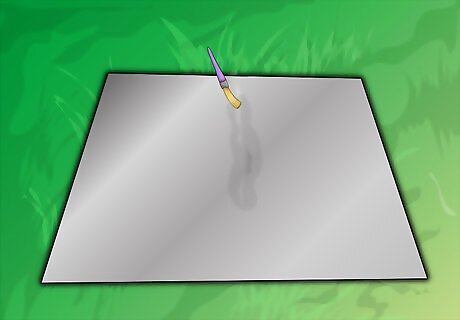

Apply the filler metal by running a brazing rod along the crack or the joint. The heat of the metal will melt the filler into the area needing the repair. Move the flame of the torch on and off as needed to melt the rod.

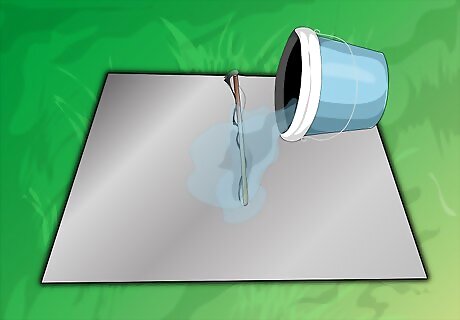

Remove the flux after the filler material has solidified by dipping the part or pouring hot water on the repair. The flux will flake off. If it does not come off, use a wire brush to gently scrub the brazed area while wet or still in the hot water.

Polish the area with an emery cloth after the metal has cooled completely.

Coat the area with a rust-resistant coating if you are not immediately finished with the area.

Comments

0 comment