views

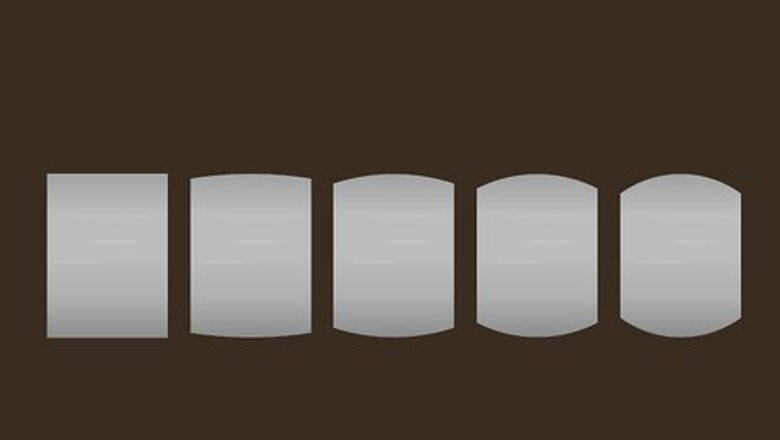

Choose the die. Usually, an English wheel comes equipped with five or six different anvil wheel dies. Choose the die according to the type of forming you wish to achieve.

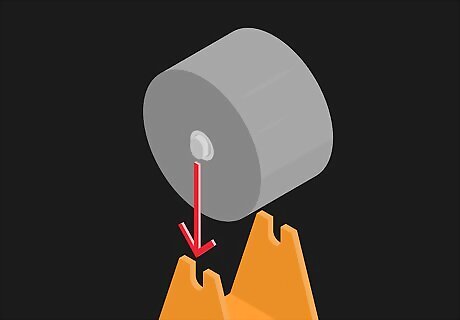

Attach the die to the frame. The lower jaw of the C frame has two carved grooves and the anvil wheel has an axle which extends on either side. Place the die onto the lower jaw by fitting the axle into the grooves.

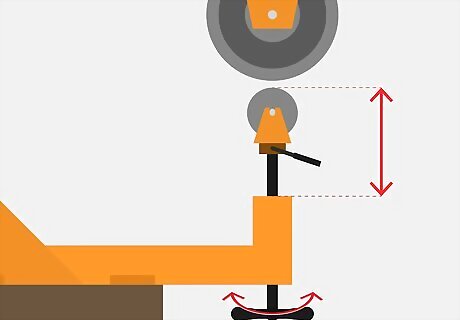

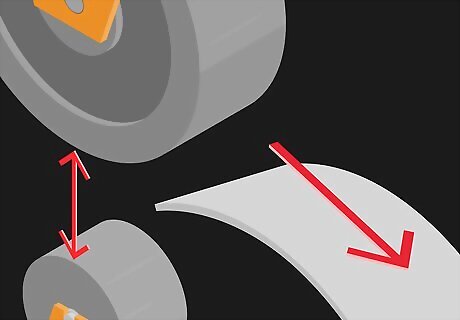

Adjust the gap between the wheels. Turn the handle under the lower jaw to adjust the space between the wheels. A smaller the gap will apply more pressure to the sheet metal.

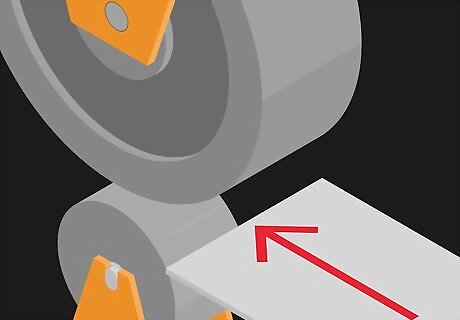

Begin the metal forming process. Pass the sheet metal through the gap between the rolling wheel and the anvil wheel.

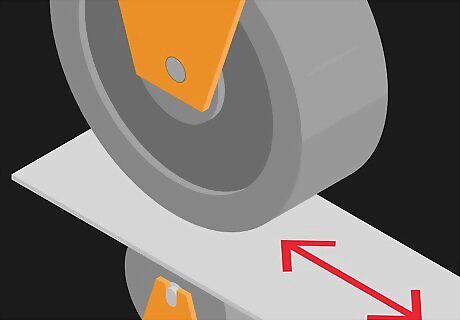

Move the sheet metal back and forth between the two dies to help form the sheet metal. Note that the sheet metal part can be manipulated in every direction.

Remove the sheet metal after forming is complete. Many English wheels are equipped with a lever just under the anvil wheel. The lever increases the gap so you can remove the sheet metal easily without changing your settings.

Comments

0 comment