views

Winding the Bobbin[1] X Research source

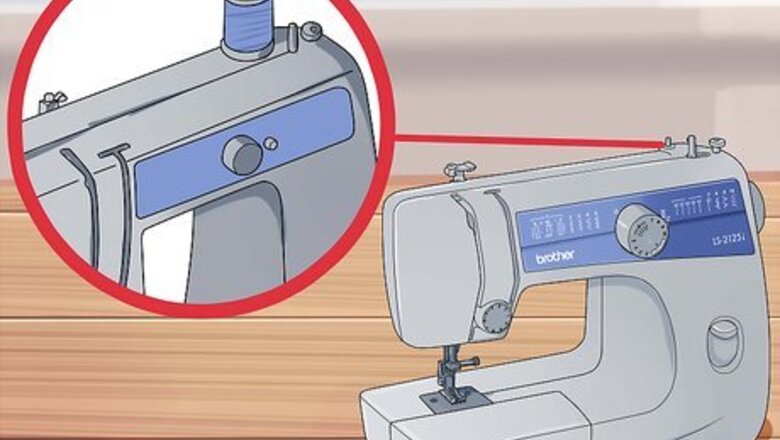

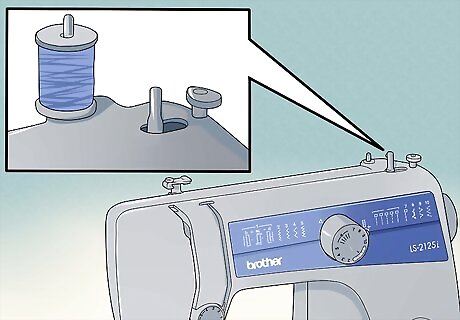

Place the spool on the spool pin. Pull the spool pin up so that it is completely vertical. Sit the spool of thread on this pin. Position the spool so that the thread winds clockwise around it. Pass the thread around the bobbin winding tension disc on top of the machine.

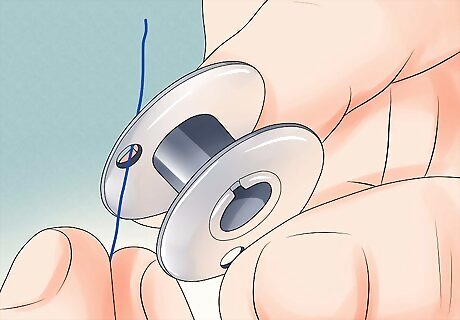

Draw the thread through the bobbin hole. Pass the tail end of the thread through the top hole of the empty bobbin. The thread should pass through the hole from the inside. The tail of the thread should end up on the outside of the bobbin. Only pass the thread through the upper hole. Do not pass it through the bottom hole.

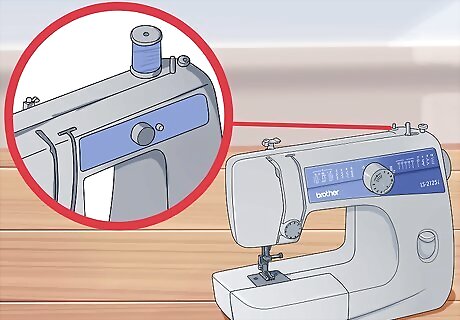

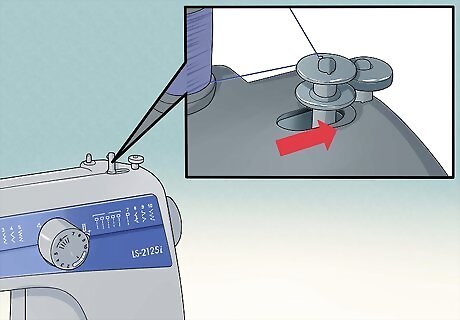

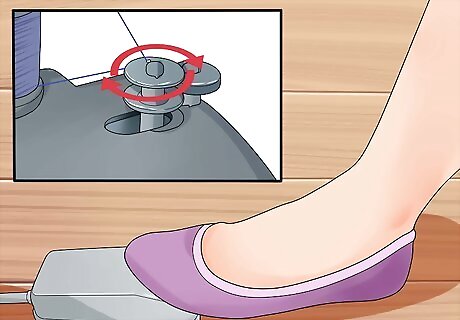

Sit the bobbin on the bobbin winding shaft. Place the bobbin onto the winding shaft, then slide the shaft to the right. Use your hands to gently twist the bobbin clockwise. After a slight rotation, you should see the spring on the bobbin winding shaft click into the slit along the side of the bobbin.

Press the foot controller. Lightly tap your foot on the foot controller of the machine. Allow the the thread to wind around the bobbin a few times. Hold the tail end of the thread with one hand as you do this. Take your foot off the controller and stop the machine after the thread is partially wrapped around the bobbin. Do not wait until the bobbin is full before releasing the controller. On some machines, you can wind a bobbin while your sewing to make the most of your time.

Trim the excess thread and continue winding. Once the thread is secure on the bobbin, trim the tail coming out from the top hole. Step on the presser foot again to finish winding the bobbin. The machine should stop on its own once the bobbin is completely full. Do not touch the balance wheel as the bobbin winds. The wheel will turn during this time, and you should not disturb or attempt to stop it.

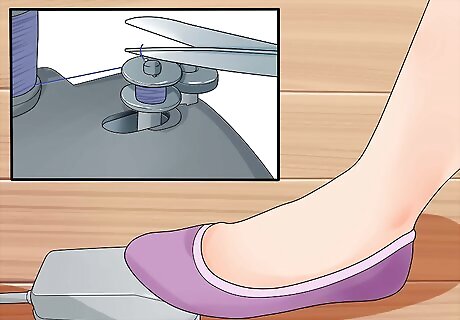

Cut the remaining thread. Once the machine stops, cut the thread connecting the bobbin to the rest of the spool. Push the bobbin winding shaft back to the left and lift the full bobbin off. Note that if the bobbin is wound improperly, the thread tension could loosen as you sew and break the needle. The thread on the finished bobbin should look tight and even. This step completes the bobbin winding portion of the process.

Inserting the Bobbin[2] X Research source

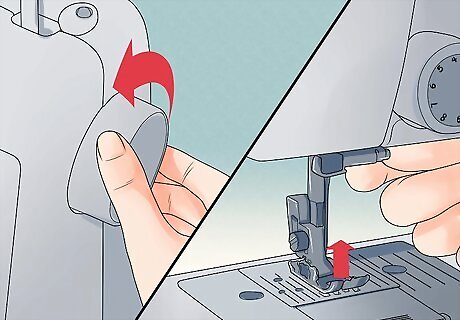

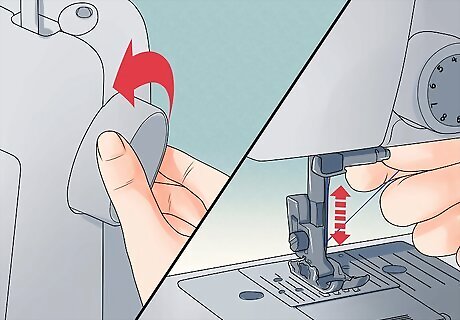

Raise the needle. Turn the balance wheel toward you, moving it counterclockwise, until it reaches its highest position. Raise the presser foot lifter to lift the presser foot, as well.

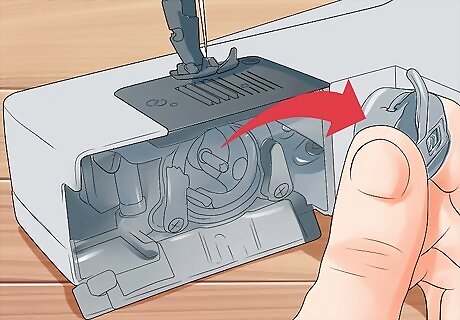

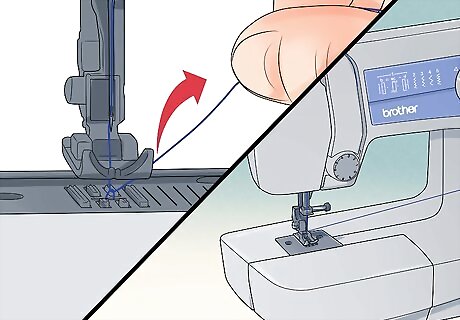

Remove the bobbin case. Open the shuttle cover to reveal the bobbin case. Pull on the bobbin case latch, pulling the case straight out through the front of the machine. The shuttle cover is located along the front side of the machine, beneath the needle and behind the extension table.

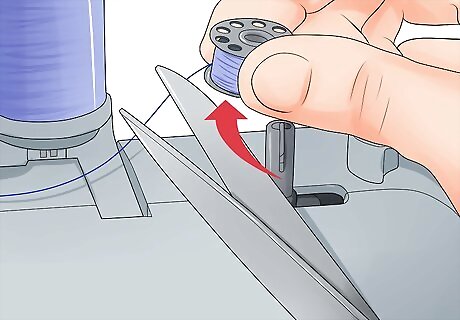

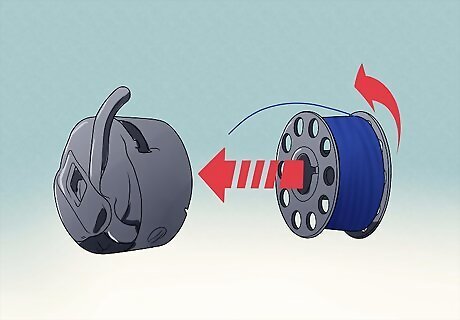

Slide the bobbin into the bobbin case. Slip the loaded bobbin into the bobbin case so that the thread comes up from beneath the bobbin. Unwind about 4 inches (10 cm) of thread from the bobbin before attempting to insert it into the case. Hold the bobbin case so that the latch points down and toward you. The thread should be directed toward the top of the bobbin case as you slip the bobbin inside. When viewed from the front, the thread should appear to wind around the bobbin in a clockwise rotation. If the bobbin is loaded in the wrong direction, the thread tension will be incorrect and you may end up breaking the machine needle as you attempt to sew.

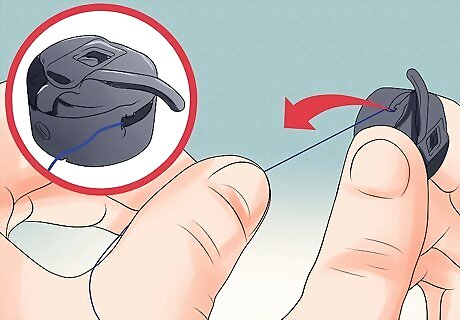

Maneuver the thread into the delivery eye. Pull the tail of the bobbin thread through the slit at the top of the case. Draw it down and to the left, working it into the delivery eye. The delivery eye is located just beneath the tension spring of the case.

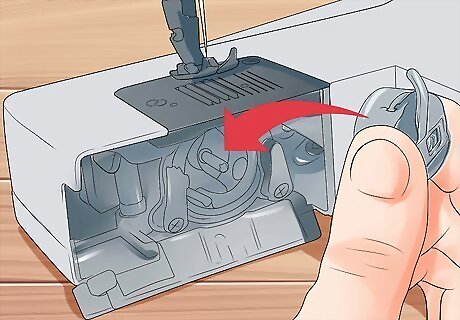

Place the bobbin case in the machine. Hold the bobbin case by the latch and slip it into the shuttle race of the machine. Release the latch once the bobbin case in in place. You will need to make sure that your index finger lines up with the top opening of the shuttle race as you push the bobbin case inside. A properly loaded bobbin case should snap into the machine. It will fall out if placed improperly or insecurely.

Threading the Needle[3] X Research source

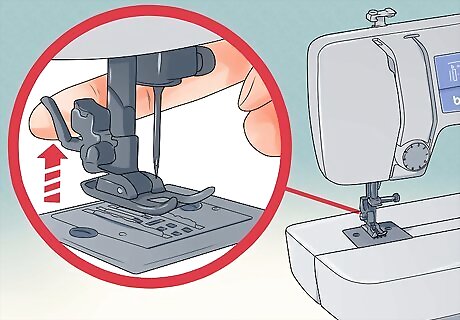

Raise the presser foot. If you have not done so already, lift the presser foot lifter up, releasing the presser foot and bringing it to its highest position.

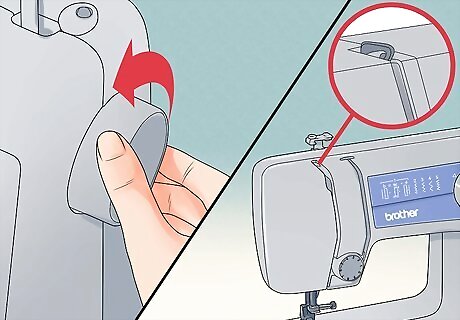

Raise the thread take-up lever. If necessary, you should also turn the balance wheel at the side of the machine toward you in a counterclockwise rotation. Continue turning the wheel until the thread take-up lever at the front of the machine is in its highest position. Only pay attention to the position of this lever; do not worry about the position of the needle. This lever will be positioned above the needle and should have a small notch in it.

Sit the spool on the spool pin. Lift the spool pin to its vertical position and rest the spool of thread on it. Position the spool so that the thread appears to wrap around it in a counterclockwise rotation.

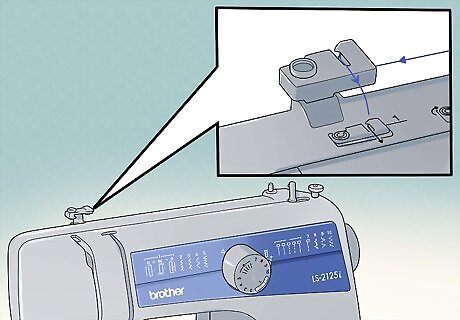

Pass the thread through both upper thread guides. Pull the thread from the spool, drawing it through the rear thread guide at the top of the machine, followed by the front thread guide at the top of the machine. The rear thread guide is directly next to the bobbin tension disc. Simply slip the thread into the gap of the guide. The front thread guide is a small notch directly in front of the rear guide. Slide the thread through that notch. Note that there should be a diagram on the top of the machine to help guide you as you thread the needle.

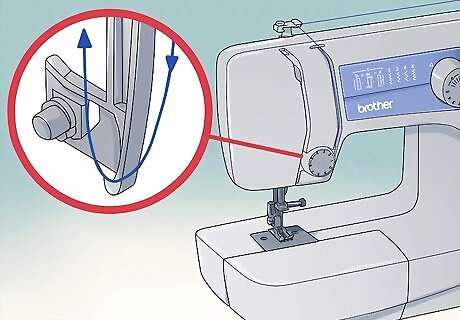

Pull the thread down. Slip the thread down into the right channel at the front of the machine. At the bottom of the right channel, wrap the thread around the upper tension control dial. The thread should pass from right to left, picking up the thread check spring and slipping into the thread tension discs behind the dial. Grab the thread on both sides of the tension dial. Gently tug on both sides to make sure that the thread is firmly in place.

Guide the thread up and around the take-up lever. Draw the thread up through the left channel at the front of your machine. Bring it all the way to the back of the channel, then slip it into the eyelet of the thread take-up lever peeking out from inside the channel. Pull the thread through the eyelet, moving from right to left. After successfully trapping the thread inside the eyelet, draw the thread back down through the left channel again.

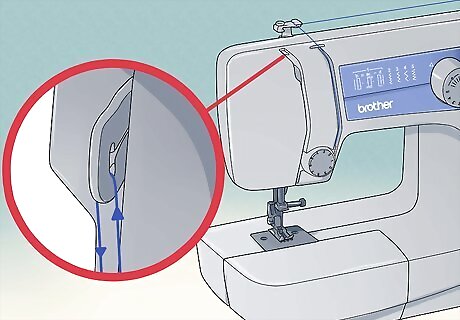

Pass the thread behind the thread guide. Slip the thread down and position it behind the wire thread guide just above the needle.

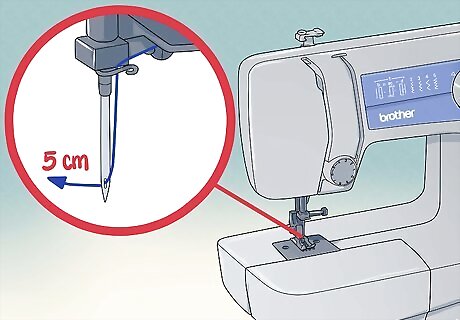

Thread the needle from front to back. Insert the thread into the needle. Bring the thread through the front of the eye and out through the back. Once the thread is successfully inserted through the needle, pull out a tail roughly 2 inches (5 cm) long. Position this tail behind the needle, pointing toward the back of the machine.

Drawing Up the Lower Thread[4] X Research source

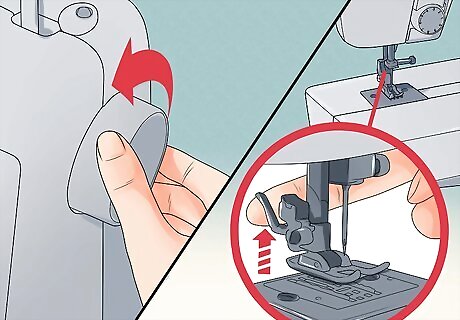

Raise the presser foot and needle. If the two are not already in their highest positions, take a moment to make sure that both the presser foot and needle are as high as possible. To raise the presser foot, simply lift up the presser foot lever/lifter. To raise the needle, turn the balance wheel on the right side of the machine counterclockwise, toward yourself, until the needle sits in its highest position.

Turn the balance wheel toward you. Turn the balance wheel toward yourself again in a full rotation. The needle should move all the way down and all the way back up. Hold the tail of the upper thread as you do this. Keep the thread taut, but do not put pressure on the needle. Note that needle must be threaded and the bobbin must be loaded during this process. During this rotation, the upper thread should catch the lower bobbin thread in a loop.

Pull the upper thread toward you. Gently tug on the thread inserted through your needle. Continue tugging until the thread looped around it pops up enough for you to grab it. This extra loop of thread comes from the bobbin. Once you can grab the loop, pull it out into a straight tail. If you cannot grab it with your fingers, use a small screwdriver, pencil, or similar object to draw the loop out.

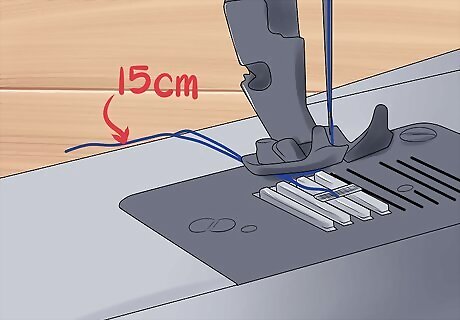

Position both tails behind the machine. Pull on both pieces of thread until you have tails measuring roughly 6 inches (15 cm) long. Let both of these tails hang off from the back of the sewing machine. Make sure that the upper thread passes in between the "toes" of the presser foot. With the completion of this step, the Brother LS 2125i sewing machine is fully threaded and ready to use.

Comments

0 comment