views

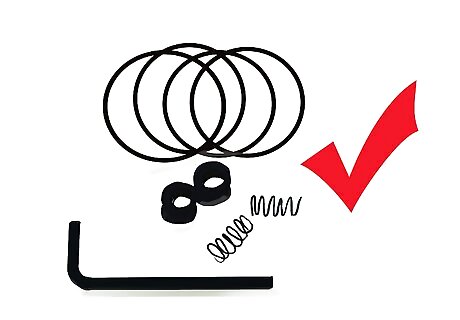

Purchase a replacement parts kit from a reputable hardware store, such as Home Depot. The kit Home Depot sells is comprehensive in that it includes all of the washers and gaskets, springs, a new ball, and the plastic inset piece for the top of the assembly.

Carefully close the shut-off valves beneath the sink. I say carefully because these are some of the least used valves in your home and they could be corroded making them difficult to turn. NEVER use excessive force, the valves are likely made of brass and brass is softer than steel. Turn on the faucet and make sure the water is turned off.

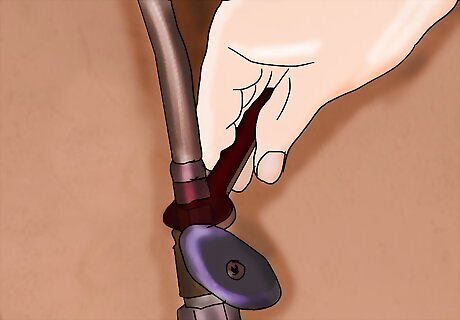

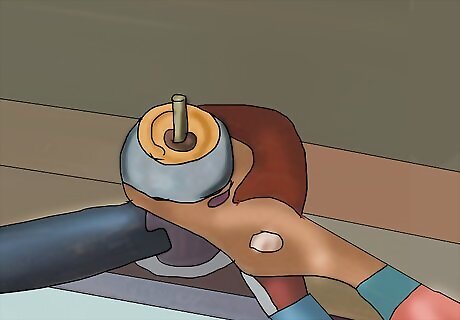

Using the allen wrench supplied in the kit, loosen the set screw that holds the handle in place. Lift the handle off of the faucet assemble and set aside.

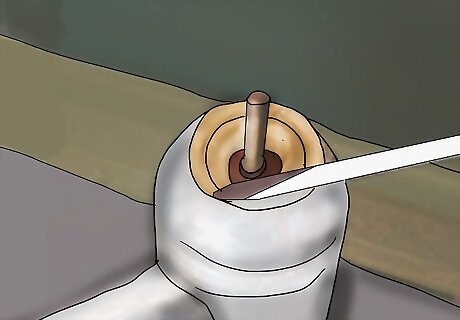

The plastic ring inset in the chrome-dome is adjustable and can be used to increase or decrease the pressure on the internal components. This threaded ring has four slots cut in it. Push in a notch with a screwdriver to relieve the force on the internal parts. You may need to tap the screwdriver gently with a hammer to get things moving.

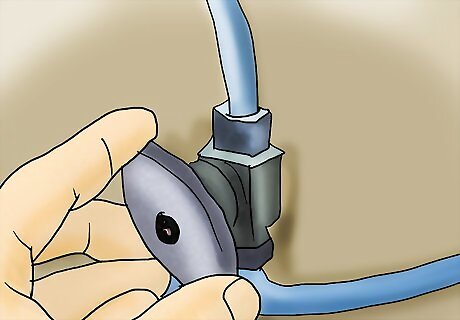

Remove the chrome-dome by turning counter-clockwise. You may need to use Channel-Lock pliers to get things moving. Set aside.

Gently remove the plastic disc which sits on top of the ball. This disc should lift off with a black rubber gasket. This gasket is what keeps the faucet from leaking around the top chrome-dome when the water is turned on.

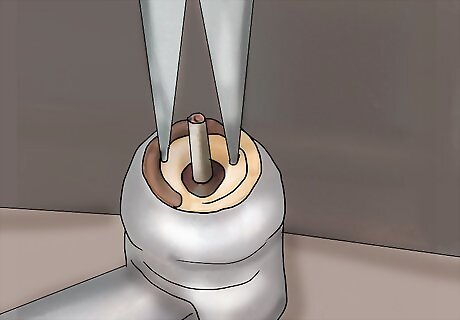

Gently remove the ball. Please note the orientation of the ball, cut into one side of the ball is a slot that rides on a stud inside the socket.

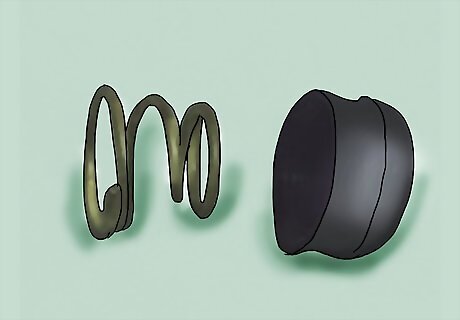

In the bottom of the socket you should see two black rubber pieces. These are the washers that keep the water from leaking when the faucet is off. These can be removed by gently prying them out with a small, flat-tipped screwdriver. Also, be sure to remove the spring.

Insert the new springs into the two holes. The large end of springs go in first and the seats (the rubber things) slip down over the spring. You should press firmly to seat the washer almost flush with the bottom of the socket. Wipe a small amount of silicon grease onto the rubber washer. This will help keep things lubricated through the life of the washer.

Repeat item #9 for the other washer.

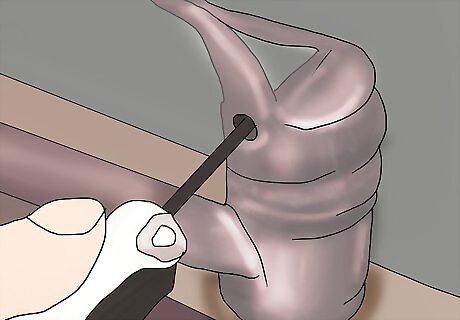

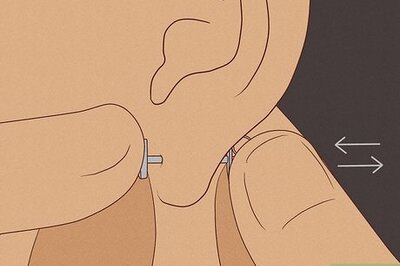

Gently remove the faucet arm from the upright shaft by pulling upward on it while rotating it.

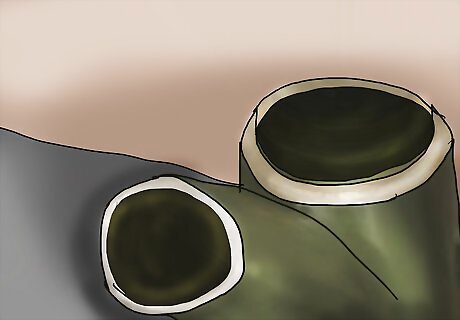

With the faucet arm removed you will see two large black washers that encircle the upright shaft. These should be removed and replaced with the corresponding washers from the parts kit. Again, apply a small amount of silicon grease to keep things rotating smoothly.

Replace the faucet arm by pressing down firmly on it while rotating it side to side. Be sure to keep the cylinder upright at the beginning, this makes it easier to get it started.

Replace the ball into the socket keeping the alignment of the ball in mind. You shouldn't have to force the ball into the socket.

Seat the large black gasket into the plastic disc and then seat the gasket & disc assembly onto the ball. Keep in mind that the disc is keyed with a slot on the left side of the upright cylinder.

Loosen the plastic ring inset into the chrome-dome. This will make it moderately easier to re-install the chrome-dome.

Install the chrome dome. This should prove to be the most difficult part of the procedure. Remember that all of the washers, gaskets and springs are new and there is a lot less leeway in the fit of things. You may have to press down on the plastic disc with a pair of needle-nosed pliers to get enough room to get the chrome-dome threads started.

Tighten the chrome-dome onto the assembly. Remember that you can loosen the plastic ring inset if you need to get that last 1/4 turn.

Tighten the plastic ring inset so that things are tight, but nothing binds. If you get things too tight you will cause things to wear quicker than normal and you'll need to do this whole procedure again sooner than not.

Replace the handle onto the shaft and tighten with the allen wrench.

Check to make sure that you don't have any extra parts.

Turn on the water at the valves and check for leaks. Start out with the water on cold and on with about half the maximum pressure. If things look OK with the half pressure then turn the cold water on all the way. Again, check for leaks. Once you're sure things are OK, turn on the hot water.

Clean up after yourself and put your tools away.

Comments

0 comment