views

Removing the Toilet

Turn the valve behind the toilet to turn off the water supply. Master plumber Dave Jones says to turn “the water valve to the right. If it’s an older style gate valve, it will require several turns before it closes. If it’s a quarter-turn ball valve, it only require turning the valve one quarter of a 360-degree turn." If this doesn’t shut off the water supply completely, turn off the main water valve near your water heater or in your garage, laundry room, or basement.

Flush the toilet and sponge up the water in the tank. Jones says to "Flush the toilet repeatedly until most of the water is out of the tank,” then “use a sponge to soak up the remaining water in the tank.” Because the water supply is shut off, the tank won’t refill. You can also use a wet vac, towels, or a turkey baster to remove any remaining water in the tank and the bowl.

Disconnect the water supply line from the toilet tank. Try to unscrew the nut counterclockwise by hand first. If that doesn’t work, Jones says to “Remove the water supply line from the bottom of the toilet tank using an adjustable wrench.” Tuck the end of the line in a bucket or on a towel to capture any water left inside. Jones recommends putting on “some protective rubber or latex gloves” for the rest of the process.

Remove the 2 anchor bolts that attach the toilet to the floor. Jones says “Remove the bolt covers at the base of the toilet pedestal to reveal the bolts and nuts.” Then, “use an adjustable wrench to loosen the nuts on the vertical bolts that secure the toilet to the toilet flange at the floor. Completely remove the nuts and washers.” If the edge of your toilet was sealed to the floor with caulk, gently rock it side to side to break the seal. The new toilet flange set should come with nuts, bolts, and washers, but keep them handy if they’re in good condition in case it doesn’t.

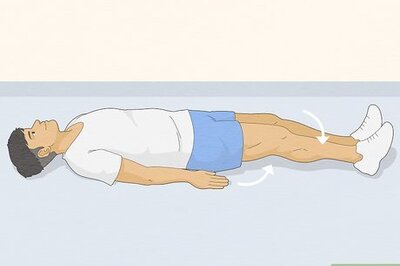

Lift the toilet straight up and place it sideways on a towel. Place a towel or two on the floor. Jones says to “Stand up and grasp the front of the bowl and the back of the tank while keeping your back straight. Begin lifting the toilet straight upward, using your legs to lift. The toilet should come free off the bolts and the old wax ring that sealed it to the toilet flange at the floor.” Alternatively, place the toilet straight down on the towels—just make sure to tilt the toilet slightly when you’re scraping off the old wax to remove the wax from the base, too. Toilets weigh between 70–120 lb (32–54 kg), so get help if you’re not sure you can lift it. To make this process easier, use a wrench to remove the bolts underneath the tank that attach to the bowl. Move the tank first, then move the bowl.

Replacing the Toilet Flange

Plug the drain pipe with an old towel or T-shirt. Push the towel or shirt securely into the pipe to prevent odors and sewer gasses from entering your home. Make sure the towel or shirt is pushed down far enough that you can reach the bottom edges of the flange. Make sure to use a towel or shirt you don’t want to wear again—you’ll throw it away after you’re done. Some people wait to block up the pipe until after removing the old flange. However, by blocking it now, you stop sewer gases earlier and prevent losing wax ring bits, screws, bolts, and other tools down the pipe.

Scrape off the old wax with a putty knife. The wax ring sits on top of the toilet flange and seals the connection between the flange and the toilet base. Scrape the wax off the flange and the bottom of the toilet bowl until both are completely clean. Jones says you can also “Use a large flathead screwdriver to pry up the old wax ring and [any] remaining remnants.” Keep some newspaper or an old towel nearby so you can wipe off your putty knife as you work. The wax will likely come off in sticky chunks.

Take off the screws that attach the flange to the floor. Use a screwdriver or drill to remove the screws (usually, there are 2 to 4) from the edge of the flange.

Remove the flange if it's made out of PVC and sealed with a gasket. If you have a gasket-sealed PVC flange, which is the most common type, you’ll be able to lift it straight up from the drain pipe once the screws have been removed. Rinse it under the sink and wipe it with a cloth. Clean the area around the drain pipe with a wet vac or damp cloth. If you have a metal flange: Call a plumber and have them finish the job for you. If the flange is glued into the pipe: Call a plumber or carefully cut the sides in 1 in (2.5 cm) sections with a reciprocating saw and remove the pieces with a chisel or crowbar. If the flange is made of cast iron and joined to a cast iron pipe: Call a plumber or carefully chip away at the lip with a chisel and rubber mallet.

Take the old flange to the hardware store and buy a matching one. Measure the interior of the exposed drain pipe and find a new flange that’s the same size and shape as the old one. Most new flange kits come with a wax ring, while others require you to buy the ring separately. If you can’t find a good match or need help in general, ask an employee at the store for help. Instead of wax, some newer rings are rubber gaskets instead. You can install these the same way you'd install a wax ring.

Put the new flange in the drain pipe and insert the mounting bolts. Jones says that the flange lip “has slots that allow you to place the two brass closet/toilet bolt heads (facing down) into the large opening of the slots.” Slide the bolts towards the end of the slots. Rotate the flange so that the bolts are “in the 9 o’clock and 3 o’clock positions, one bolt on each side of the flange.” Read your local plumbing codes to see if you’re required to glue the flange to the drain pipe. If you are, carefully apply the glue to the bottom of the flange and the inside of the pipe. If your flange has a stainless steel ring around the outside, simply spin the ring so the bolts are in the correct positions. If the lip of the flange won’t rest flush with the wood floor, the floor may be warped or damaged. You may need to hire a pro to replace the floor or subfloor before continuing.

Drive screws through the flange and into the flooring. Use a drill to create pilot holes in the flooring, then drive the screws into the holes. If the subfloor is concrete, use a masonry drill bit and screws made for concrete. If your subfloor is made of wood, use wood screws. Some kits come with 2 or 4 screws, while others have up to 6.

Push the new wax ring into place over the flange. Press the rounded side of the wax ring over the pipe stub that surrounds the opening on the bottom of the toilet. Press firmly around the wax ring, but try not to deform it. Alternatively, lay the wax on top of the toilet flange, then set the toilet on top of it. Jones recommends following the “directions on the package so that it is installed properly.” If you’re using a flange that comes with a rubber gasket, lay it rounded-side-up on the toilet flange and place the toilet on top of it.

Remove the towel or T-shirt from the outflow pipe. Pick out any pieces of wax ring, loose screws or washers, and other objects before removing the towel or shirt to prevent them from falling down the pipe. Dispose of the shirt or T-shirt.

Reinstalling the Toilet

Set the toilet straight down on top of the flange. Line up the holes in the toilet base with the 2 bolts that protrude from the flange. Once the toilet is resting on the flange, press down firmly near the back of the bowl rim to deform the wax ring and seal the connection. This process is the same whether you press the wax ring to the underside of the toilet or place it on top of the flange.

Place the washers and nuts onto the bolts on either side of the base. Put a plastic washer onto each bolt first if they’re included in your kit, then place the metal one on top. Hand-tighten the nuts clockwise before using an adjustable wrench to tightly secure them. Be careful not to overtighten the bolts—this can cause the porcelain or the new flange to break. If you have plastic caps that cover the bolts, snap them in place. If the bolts are too long, trim them with a hacksaw so that the plastic caps will fit over them.

Reconnect the water supply hose and turn on the water supply. Hand-tighten the nut at the end of the metal supply hose onto the connection point on the underside of the toilet tank. Use an adjustable to finish tightening the coupling if needed. Turn the oval-shaped valve counterclockwise to turn the water back on. Plastic couplings usually only need to be hand-tightened, while metal ones can be tightened with a wrench or pliers.

Flush the toilet multiple times to check for leaks. Carefully check the floor around the base of the toilet. If it stays dry, you’re all set. If you see any water seeping out, you’ll need to remove the toilet and try again—or call a plumber. Apply bathroom caulk to the bottom edge of the toilet if your local plumbing codes require you to.

Comments

0 comment