views

Removing Light Scuffs with a Scouring Pad

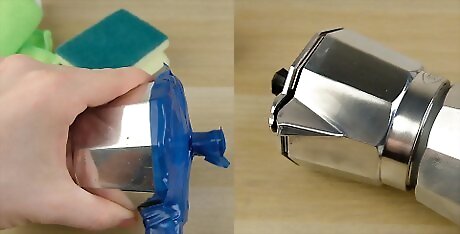

Mask off any non-metal areas around the scratched aluminum using tape. Use strips of blue painter’s tape or masking tape. Cover up any sensitive or delicate parts of the aluminum object that you don’t want to accidentally scratch or get polishing compound on during the polishing process.Warning: Never attempt to polish aluminum that has a special coating or you will just damage the item even more. For example, an aluminum pan with a non-stick coating. Check the manufacturer’s specifications in the owner’s manual or online if you aren’t sure whether something has a coating. For example, if you want to polish scuffs out of something like an aluminum stove or fridge, you might want to mask off things like control panels if they are near the scratched area. This method works for very minor scuffs and scratches. Keep in mind that you won’t be able to get the aluminum looking like it is straight out of the factory, but you will be able to hide the scuffs and shine up the metal. You’ll get the best results using this method if you polish the entire aluminum surface, not just the scuffed area, so that the finish looks uniformly shiny when you’re done. However, if the scuffed area isn’t too conspicuous, such as in a corner of an aluminum stove door, you can just polish the scuff marks out and blend it in to the surrounding metal as much as possible.

Rub a scouring pad back and forth over the scuffed area, going with the grain. Hold a scouring pad in your hand and press it gently against the scratched area of the aluminum. Rub it back and forth over the area using slow controlled motions until the scuff marks disappear and the metal starts to look shiny. Most aluminum has a unidirectional grain, which are actually brush marks caused by the original polishing process that the aluminum went through. Never rub the scouring pad across this grain or you might end up making the scuffs worse. If the aluminum item you want to polish doesn’t have a visible grain, just pick a direction to rub the scouring pad in and only move it back and forth in this direction. Don’t change directions or move it in circular motions or you might just create more scuff marks. Scouring pads are also known as buffing pads. The finer the git, the better for this job. You can get a fine-grit scouring pad at an auto detail supply shop.

Apply metal polish to the aluminum using a microfiber cloth. Squeeze a small drop of metal polish onto a microfiber cloth. Scrub the metal polish into the affected area and the surrounding aluminum surfaces using back and forth motions and going with the grain of the aluminum. Keep rubbing until the polish disappears into the metal and the surface looks nice and shiny. You can use a special aluminum polish or any type of metal polish you have available, such as a pewter polish. Both will work to shine up the surface.

Use a microfiber cloth to apply metal wax or sealant to the aluminum. Wrap a microfiber cloth around your index finger and dip it into a container of metal wax or sealant. Rub it over the aluminum surface using even strokes in alternating directions until the wax or sealant gets absorbed and there are no streaks on the metal. This will seal the aluminum and protect it from oxidation and corrosion. You can get metal waxes and sealants at an auto detail supply shop or at a hardware and home improvement store in the paints and coatings section.

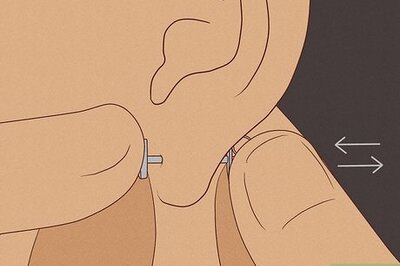

Remove any tape that you applied to mask off certain areas. Peel up the masking tape or blue painter’s tape. Dispose of it in your recycling bin.

Sanding out Deep Scratches

Spray WD-40 all over the aluminum you want to polish to lubricate it. Cover the scratched aluminum surface evenly in WD-40. This lubrication will help carry away the metal particles that you remove during sanding. This method is known as wet sanding. You can do it with water too, but WD-40 is the best lubricant when you are sanding bare metal. You can use this method to sand and polish out curb damage on an aluminum car wheel or bicycle crank shaft, for example. Since you’ll be actually removing a layer of metal using this method, the final results will look best if you sand and polish the entire aluminum object, not just the scratched part. For instance, if you want to polish scratches out of the face of an aluminum wheel, sand the entire wheel down.

Sand out the scratches using 220-grit sandpaper. Attach 220-grit sandpaper to a sanding block, an electrical sander, or just use it in your hand if the scratched area is small. Press the sandpaper firmly against the scratched area and move it back and forth over the scratches in alternating directions until they disappear.Warning: Don’t ever use sandpaper that is coarser than 220-grit on aluminum as it will just create more deep scratches in the metal. Keep in mind that if there are very deep dents and gouges in the aluminum, you won’t be able to polish them out completely by sanding. However, you can at least make them less visible and restore shine to the surrounding surface. Make sure that the sandpaper you used is labelled as safe for wet sanding. Most fine-grit sandpaper is OK to use for wet sanding, but double-check the packaging or the back of the paper to be sure. Wear safety glasses and a dust mask when you sand metal, especially if you are using a powerful electric sander.

Switch to 1500-grit sandpaper and sand the aluminum to smooth it out. Move the sandpaper back and forth in alternating directions, applying firm pressure, all over the same area you just sanded the deep scratches out of. This will get rid of the small scuffs and scratches made by the coarser sandpaper to smooth out the surface and start shining it up. If you don’t have exactly 1500-grit sandpaper, it’s fine to use another very fine-grit sandpaper. Anywhere between 1000-grit and 2000-grit is fine for this step.

Give the aluminum a final sanding with 3000-grit sandpaper. Switch to 3000-grit sandpaper and go back over the entire surface you have been sanding. This will make the aluminum very shiny. If you don’t want a super-shiny, mirror-like finish, you can use sandpaper that is slightly less than 3000-grit to finish sanding. For example, something between 2000-grit and 2500-grit. If there is no more WD-40 left on the aluminum by this stage, spray a little directly onto the sandpaper to lubricate it for this last round of sanding. This will help make the aluminum extra-shiny and carry away fine metal particles so they don’t stick to the surface.

Rub aluminum polish onto the surface using a polishing pad or cloth. Put some aluminum polish onto a clean area of a polishing pad or polishing cloth. Work the polish into the aluminum using circular motions, starting in the center and working your way out to the edges. You’ll know the polish is doing its job when the polishing cloth or pad starts to get black. If you don’t see this black residue on your cloth or pad, rub harder and keep working the polish in all over the surface until you do.

Buff the polish off with a clean, soft cloth. Rub a clean, soft cloth, such as a microfiber cloth, vigorously all over the polished surface using circular and alternating back and forth motions. Keep buffing the aluminum until it is uniformly shiny and there are no traces of polish left on the surface. You can keep buffing the aluminum until you achieve the level of shine you want. However, once there are no streaks or other residue from the polish left on the surface, feel free to stop.

Comments

0 comment