views

Acquire the tools and materials necessary to make the box. The items are: a hammer, small box of 8 penny (1 and ½ inch galvanized) nails, one 10 foot long pine (1 inch x 8 inch) wood plank, circular saw, jig saw, safety goggles, tape measure, pencil, speed or “T” square, drill, 1 inch paddle bit, wire (old phone cord would work), a wooden dowel (approximately broom handle width) 3 feet in length (long enough for a 18 inch and 11 inch sections), bait can, and some form of bait.

Cut the materials to size. Using the circular saw, cut the 1 x 8 pine plank into: three lengths of 2 feet (bottom and side boards), 1 length of 22 inches (top board), one length of 9 inches (back board), one length of 10 inches (door board), four lengths of 1 inch (rail boards), and one length of 2 inches (fulcrum board).

Then cut the wooden dowel into one length of 11 inches (trigger) and one length of 18 inches (lever).

Lastly, cut two 8 inch lengths of the wire.

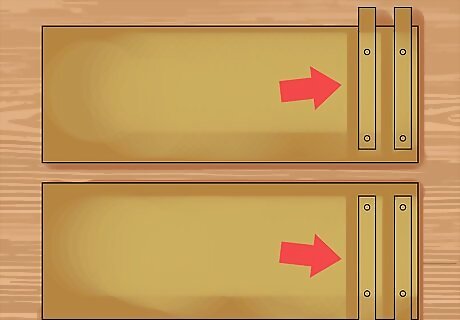

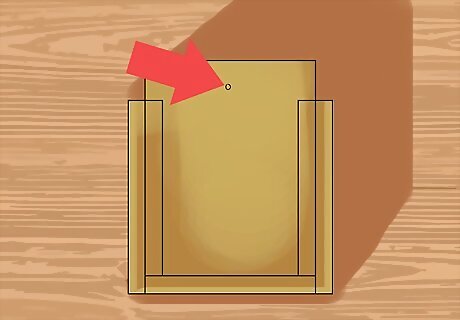

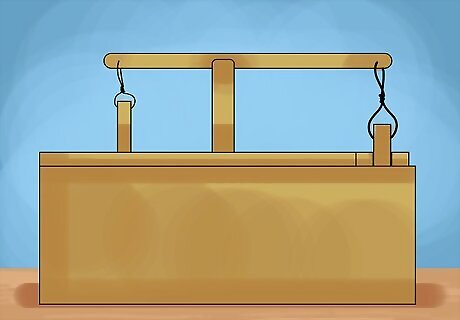

Attach the rails to create a channel for the door. Using two of the three two foot lengths, attach the rails (four 1 inch length) to the front of the side pieces. This is done by first nailing the 1 inch length flush with the end of the side board but raised ¾ inches above the top, use at least two nails per rail. The second rail is spaced 1 inch from the initial rail and runs parallel to it. Using a speed-square will assist with correct spacing. Unlike the initial rail this second one will be flush with the top and bottom of the side board. The channel formed by the rails must have consistent one inch spacing to ensure the door slides properly. This should be repeated on the other side board.

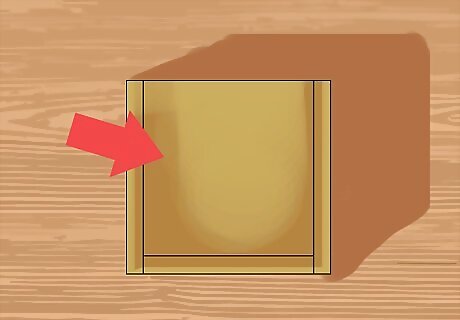

Nail the side boards to the bottom board. Lay the bottom board on its side so that the underneath portion of the board is facing the assembler. Lay the right side board, with rails facing up, parallel to the top/inside of the bottom board. The ends of the bottom and side board should be flush with one another. Nail the two boards together, making sure to drive no less than four nails through the bottom board into the right side board. Now, the left side board can be attached to the bottom. This is done by rotating the partial assembly 180 degrees. With the underneath portion of the bottom board still facing the assembler, lay the left side board, with the rails facing up, parallel to the bottom board. Make sure the rails of both sides are facing one another at the front of the trap and that the side and bottom form a 90 degree angle. Note that the ends of the side of the end of the side and bottom boards should be flush.

Attach the back board. Place the back end of the trap toward the assembler. Position the 9 inch length so that it is flush with the bottom and side boards, but uneven with the top leaving it ¾ inches above the top of the side boards. This will allow the top board to be flush with the back board once it is attached. Drive the nails through the back board into the edge of the side and bottom boards, using no less than two nails for each of the three boards.

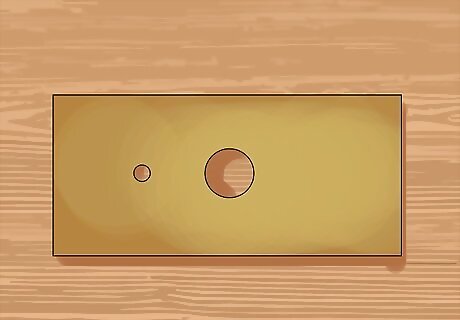

Prepare the top board. Place the 22 inch length top so that a hole, using the one inch paddle bit, can be drilled 4 ½ inches from the rear and three and ¾ inches from the side of the board. After drilling the hole, make sure the edges of the hole are smooth. A “V” shape notch is removed (cut) from the end of the fulcrum board by the jig saw. Then nail the non-notched end of the fulcrum board 10 ½ inches from the front of the top board; making sure that it is equal distance from each side and that the “V” notch is visible from the front and back of the top board.

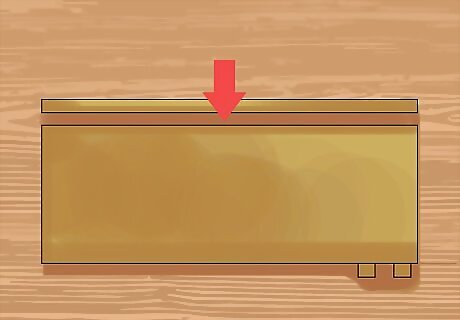

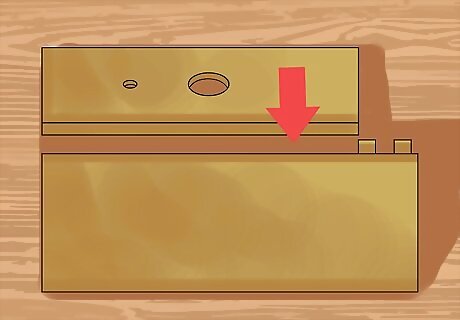

Attach the top board to the assembly. Place the top board on the assembly, making sure it is butted up against the back board and flush to the sides prior to attaching it. The hole in the top board will be closer to the back of the trap and the fulcrum is extended up. Then nail through the top board into the edges side boards, four nails for each of the sides. Two nails will then be driven through the back board into the edge of the top board.

Prepare and place the door. Using the 1 inch paddle bit, drill a partial hole 1 ½ inch from the top of the door (ten inch length), making sure the center is equal distance from each of the sides. The depth of the partial hole should be approximately ½ inch and should not completely penetrate the board. With the partially drilled hole facing inward slide the door into the rail channels, making sure the door smoothly slides up and down.

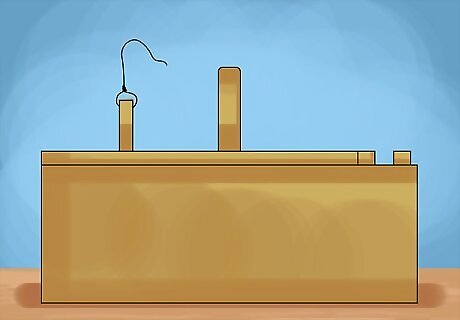

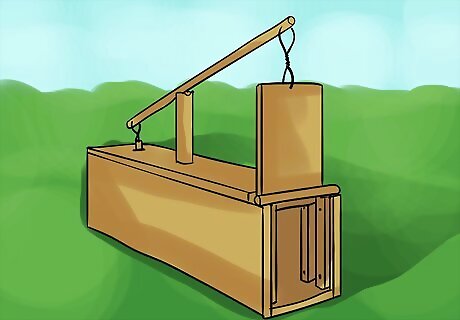

Prepare the trigger dowel. Drill a hole, 1inch from the end of the trigger dowel, using an 1/8 inch bit; making sure the hole is equal distance from each side. Place one of the two wires through the hole and knot is on one end. A notch that goes halfway through the trigger dowel is cut 5 inches from the bait end and continues 2 inches toward the lever end. Make sure that the notch can catch onto the underside of the top board, but will easily be tripped.

Prepare the lever dowel. Drill a hole, using an 1/8 inch bit, 1 inch from the end of the lever dowel. Place the wire, previously run through the trigger dowel, through the lever dowel hole and knot the wire so the trigger and lever are closely connected; making sure the ends of the two dowels do not bind.

Set the trap. A can containing bait is placed in the trap, directly beneath the trigger dowel hole. The trigger dowel is slid through the hole in the top of trap with the notch facing the front of the trap. The lever dowel is placed on the fulcrum notch and the end of the dowel is inserted into the door notch while the door is in the open position. At the same time, the notch of the trigger dowel must catch the underside of the top of trap. The trap is now ready to be used.

Comments

0 comment