views

Starting Off

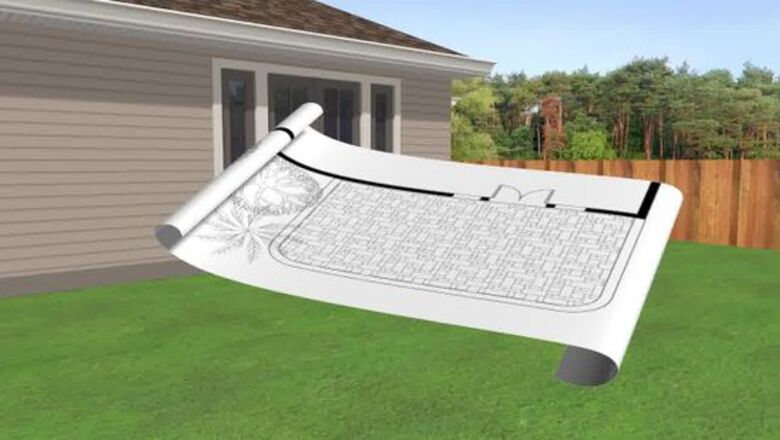

Make a plan. A good plan is essential to a successful paver project. Think about where you want your path, driveway, or patio, and then use graph paper to make a scaled drawing of the immediate area. Draw in your paver project. You'll have to play around with your design a bit, so be sure to use pencil and keep your drawing neat. Your project will need to have adequate drainage if you want it to be safe and durable. You'll also want to make sure that it slopes away from your house and other structures. To ensure adequate drainage, you should have a slope of at least 1/8" per linear foot (1/4" slope per linear foot is often recommended).

Check with your local utilities company before starting any construction. Installing pavers may be easy, but it's necessary to check with your local utilities company before beginning to ensure that you don't accidentally strike or obtrude any cables or pipes. You can do this by calling 811, also known as the Digline. When you call, you can request to have your local utility companies come to your site and mark the areas where there are pipes and wires.

Choose the pavers. You have a lot of choices in the pavers you use. Most are brick or concrete, but you can find a variety of sizes, shapes, and colors. Find a style that is to your liking either online or at your local builders supply store. In general, if your project area isn't too irregularly shaped, you can safely calculate how many pavers you need by simply measuring the square footage of the footprint and adding 5%. If your design has a lot of curves, get an extra 10% over your best square footage estimate. You should order a bit extra because you'll almost certainly end up having to cut some of the pavers to get the right fit. The fancier your outline, the more pavers you'll have to cut. Keep in mind that pavers are extremely heavy. It is best to have them delivered for this reason. There may be a pallet fee as well. There are a few things to keep in mind when shopping for pavers. For instance, pavers can range in price from quite affordable to quite pricey, so it's important to set a realistic budget before beginning your search. Make sure to think about the surface you're paving over and its intended use. For example, driveways require a sturdier, heavier paver that can support cars driving over it.

Mark the area with white marking paint. White marking paint works well and helps the locate service see exactly where the work area. Another option is to outline the project area. You can use string or garden hose to outline your project. Drive stakes to hold the outline in place and use a triangle to make clean corners.

Scope your slope. To avoid water pooling on your pavers, you want your pavers to be slightly above the surface of the surrounding ground at all points. Thus, when planning the slope, begin with what will be the highest point. Typically, this is the point at the bottom of the front door or otherwise closest to the house. Drive a stake at the high point, and mark the correct height where the pavers will meet the door or structure. Tie a string around the stake at that height. Drive a stake (if there isn't already one) at the outer boundary of your project. This will be your lowest point. Attach a line level to your string and then tie the loose end of the string around the outer stake at the height at which the line level tells you the entire string is level. Now from that line move down the stake at least 1/8" per linear foot (e.g. if it is 8 feet from your front door to the outer edge of your patio, move down the stake 1"), and draw a new line. Move your string down to this line. String cross-lines down the length of the project to ensure you mark the correct depth across the entire project. If your project area has a variety of slopes, or if your design is irregular, you'll need to repeat this process in several points. It is absolutely critical that you get the slope right, so the more stakes, the better. You may want to consider hiring someone who knows how to use a transit or laser level and measuring rod. They can achieve the same results in less time. Make sure to remove the string before you start digging, or you may end up tripping on it.

Excavating the Space

Excavate the installation area. Spaces which will be exposed only to foot traffic generally need 4-6" of base material, while driveways or projects in very wet soil may need as much as 12" of base. Figure out how deep your base will need to be (consult the manufacturer or your building supply store), and add about 1-1.5" for the sand layer, plus the thickness of the pavers (this varies by brand and style but is typically 2 3/8" or 3 1/8"). The sum of the depth of the base, the sand, and the pavers will be how deep you need to excavate your project area. Be sure to excavate 6-12" beyond the boundaries of the project to give you ample space to install your edge restraints. This is important. Also, try to level and smooth out the soil where the paver edging will go. You can also spread the base material a little past where the edging will be and then flatten it out using a compactor or hand tamping tool. Then, install the edging firmly. Measure the depth of your excavation from the string you used to track your slope, not from the surface of the ground.

Choose your base material. Base material is usually coarse, crushed stone with sharp irregular edges. The two most important things about base material is that it remains strong when compacted (to serve as a base for your pavers) and that it drains properly. Poor structural integrity and poor drainage can ruin an otherwise perfect paving project.

Lay the base. Add no more than 6 inches (15.2 cm) at a time to the entire excavated area, and then compact with a hand tamper (for very small projects) or a mechanical plate compactor. It's essential that the base be well-compacted. Repeat this process until you have a base of the correct depth. Now is your last chance to properly adjust the height of the finished project and to ensure you don't have any dips or bumps. Slightly increase or decrease the thickness of the base as necessary, taking frequent measurements from your strings to the base. Be sure to lay base material beyond the planned boundaries of the pavers. Laying the base outside the boundaries of the pavers will make your project more stable. Continue adding base material and then compacting every 2 inches (5.1 cm) until you are about 3 inches (7.6 cm) from your desired finish height. When compacting, be sure to maintain a gentle slope — usually away from your house.

Install the edge restraints. Edge restraints will help hold the shape of your project over the years. Place these restraints, usually made of plastic, aluminum, or steel, around the perimeter of the project and secure them into the ground with 12" spikes. If your design is irregularly shaped, you'll need to cut the restraints in order to follow the edges of your design.

Put down a layer of sand. The sand is the material that holds your pavers in place. Use coarse sand and screed it smooth to a uniform depth of at least 1 inch (2.5 cm), but no more that 1 1/2 inches (5.1 cm). If your project is large, lay down 1" screed pipes and then pour the sand in between the pipes, screeding the sand in small sections (50-100 square feet each). Remove the pipes and then fill in the gaps with more sand. Check to see if a weed barrier or weed blocker fabric will be used first. Most often these materials are placed on the soil before the base goes down.

Installing the Pavers

Start laying the pavers along the longest straight side. Luckily, laying pavers is easy compared to all the work you've just done. Begin laying pavers at a 90-degree corner, preferably one that abuts the house or another structure, and continue extending the pavers along the longest straight side. Be sure to pull from several pallets of product in order to have a good blend of the colors. Pavers are made from natural materials that can cause slight changes to the appearance of the colored pavers. Working from several pallets will help to blend these slight differences into the surface. Work out from there, keeping your pavers in straight lines. Lay pavers by placing them straight down in the sand --do not slide them along the ground or kick them into place and disturb the sand. Slide each paver straight down the edge of the adjacent paver. Keep the pavers as close together as possible. If there are wide gaps between the pavers, then you will need much more polymeric sand to fill the gaps. Periodically check to make sure the pavers are flat, using a string or a level to check each row for straightness. Use a level on top of the pavers often to make sure the correct slope and level is maintained from row to row. Do not walk on your prepared sand. Stand on the pavers you have already installed and work your way out. Don't get too close to the edge of the pavers you've installed, or you might disturb the sand in front of them.

Cut pavers as needed. You'll almost invariably need to cut some pavers to fit the edges. Don't try to curve your pavers to fit the edging. Instead, lay all the whole pavers you can in each row and then go back and cut pavers to the correct sizes to fit the edge. Use a masonry saw (wet saw that you can rent from a local tool rental company) or a guillotine-style splitter to make good, clean cuts. If you gave yourself plenty of pavers to work with in the beginning, you should have more than enough materials to accommodate even a few mistakes!

Tamp the pavers into the sand. Once the pavers are all placed according to pattern, use a plate compactor to tamp the pavers into the sand. Once all the pavers are installed, run the plate compactor over them at least three times to ensure they are snugly pressed into the sand. If there are any gaps between the pavers, then you can sweep polymeric sand into all the joints until they are about half full. This will keep the pavers from shifting during plate compaction. If the pavers are loose when you are compacting them, then they may become uneven. When you are compacting the material and pavers, always try to go in different directions or patterns. Be sure to use a protective covering, such as a heavy gunnysack, over your plate compactor when you compress the pavers in order to avoid scuffing.

Sweep sand into the joints. Fill the joints between pavers with coarse sand like you used earlier, or use slightly finer sand, such as bagged silica (available at paver outlets). Pour it onto the pavers and sweep it into the cracks until they are completely filled. This sand "locks" the pavers in place. Make sure the sand is dry. Use a large push broom for a large area, or a small push broom for a small area. Sweep in many different directions.

Seal your pavers. For added durability and lower maintenance, seal the pavers with an appropriate sealing product. Look for a non-toxic (vegetative safe) paver sealer, and don't forget to clean the pavers beforehand. Don’t use too much water when cleaning the pavers and make sure that they are completely dry before applying the sealant.

Comments

0 comment