views

X

Expert Source

Art FrickeHome Renovation & Repair Specialist

Expert Interview

This article will provide necessary tips to minimize issues with unstable subfloors.

Preparing for Installation

Determine the maximum practical thickness that is possible for the combination of tile, underlayment and setting materials in your project. It is necessary to consider adjoining floors (e.g. carpet or wood), height of toe kicks (beneath cabinets) and even the aesthetics of the base molding where the walls meet the floor. Example: An adjoining wood floor may have 5/8 inch thick material (~16mm). If you use 1/2 inch underlayment and 3/8 inch tile with 1/8 inch of setting material, your tile floor will have a total of 1 inch (~26mm) of thickness. This means that your finished floor will be 3/8 inch (10mm) taller that the adjoining wood floor. Transition strips may be available to accommodate this height difference, but you may be able to compensate with your underlayment by choosing 1/4 inch thick cement board instead.

Determine the stability of the subfloor. If you can feel the subfloor flex as you walk or bounce on it then you will need to use a thicker cement board. If it flexes too much you may want to consult a professional. Assuming the subfloor is relatively stable you may use a 1/4 thick cement board safely. If there is some flexing then you will need 1/2 inch concrete board.

Installing the Cement board

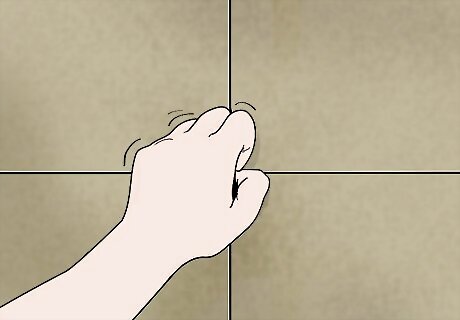

Dry fit your sheets of cement board to the area you are tiling. To cut the board you can either use the side grinder with diamond blade, or you can score and break the material. The tile department personnel can show you the available scoring knives. Your joints between sheets should not exceed 1/8 inch. It is also advisable to install the sheets perpendicular to the direction of the subfloor. This adds additional strength and stability.

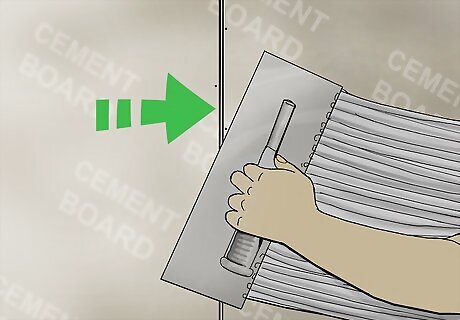

Install the sheets one at a time. Mix your thinset according to the instructions on the bag. Lift one sheet (leave the rest in place) and spread thinset directly onto the subfloor filling the area left by the sheet (use a 1/4" x 1/4" notch trowel). Once you have filled the space place the sheet down onto the thinset. Secure the cement board with the screws using the pattern directed by the board manufacturer. Repeat with the remaining sheets of cement board until finished.

Apply the crack suppression membrane over the joints of the boards. You will use the flat trowel to apply a thin layer according to the manufacturers specifications. (e.g. 6-18" width across the joint). This will distributed the stress caused by movement of the subfloor and prevent cracking in your tile. If greater protection is desired you can cover the entire floor with the membrane. Let dry for 24 hours.

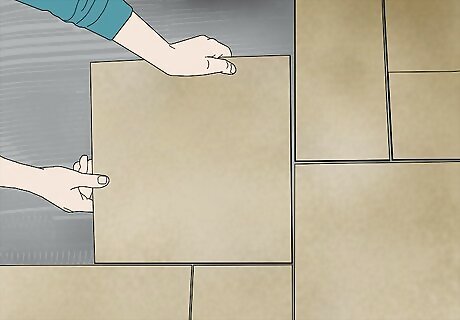

Complete the installation. The remaining steps are identical to installing tile on a concrete slab, less one tip: Use a damp sponge to wipe the cement board prior to applying thinset. This will keep the cement board from drying the thinset too fast and allow proper adhesion to the tile.

Comments

0 comment