views

Replacing Uneven Casters

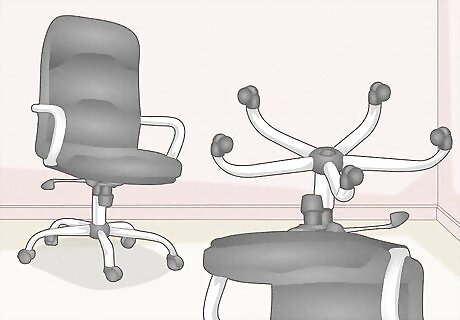

Check for uneven casters with the chair both upright and upside-down. If a caster—one of the wheels at the bottom of the chair that can rotate both vertically and horizontally—is bent or deformed, the chair will lean in its direction. With the chair upright, confirm that each caster is in contact with the floor. Then, flip the chair over and check each caster for signs of damage. Casters can bend or break due to uneven weight distribution, manufacturing flaws, or general wear-and-tear. If your chair is on a very uneven floor, the casters won’t all touch when you’re not sitting in the chair, and you’ll lean to the “low” side of the floor while sitting. You can’t really blame the chair for that!

Buy a matching set of new casters if you find any broken ones. If you spot a bad caster, your best move is to pull and replace the entire set. It’s hard to buy a single replacement caster anyway, so it makes sense to replace them all with a new set. Contact the manufacturer of your office chair, give them your chair’s model number, and order a set of matching casters. Alternatively, wait until you pull off all the old casters, then take one with you to an office supply store and use it to find a matching replacement set. Pay particular attention to matching the shape and size of the caster stems, which insert into sockets at the bottom of the chair. If all the casters are in good shape, and the chair is on a level floor, skip ahead to checking the second most likely cause of a leaning chair—the seat plate.

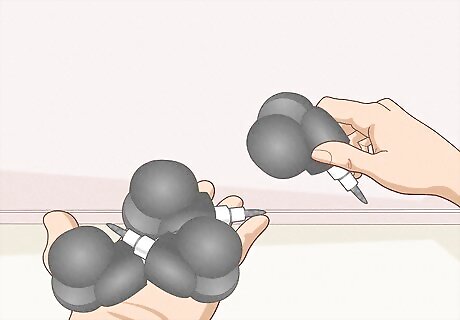

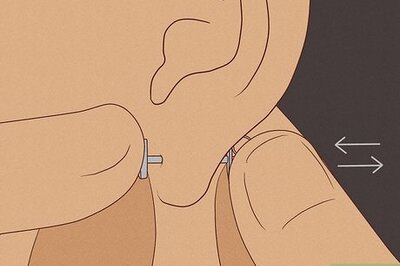

Pull each caster straight out to remove it. Most office chair casters are secured simply by the snug fit of the caster’s stem into the chair’s socket. Grasp the wheel of the caster with one hand and the bottom of the chair with your other hand, then pull firmly. More likely than not, the caster will pop out. If you can’t pull a caster free with your hands, wedge the blade of a flat-head screwdriver into the small gap at the meeting point of the caster and the chair. Use the blade as a lever by slowly working it back and forth. Once you’ve worked about 1 cm (0.39 in) of the caster stem out of the chair socket, pull on the caster wheel again. In rare cases, the casters are secured to the bottom of the chair with screws. If you see screw heads where the caster connects to the chair, use a screwdriver to loosen the screws and take off the caster.

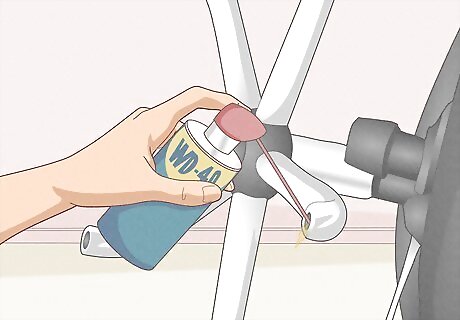

Apply a small amount of spray lubricant to each chair base socket. Use a spray lubricant like WD-40 for this job. Insert the straw into the spray nozzle, stick it into each socket, and give each a quick spray—half of a second per socket is plenty. Casters usually pull out of the sockets more easily than they go into them. Lubricating the sockets makes the process easier. If you don’t have a lubricating spray, rub a pea-sized amount of petroleum jelly (e.g., Vaseline) onto the stem of each caster instead.

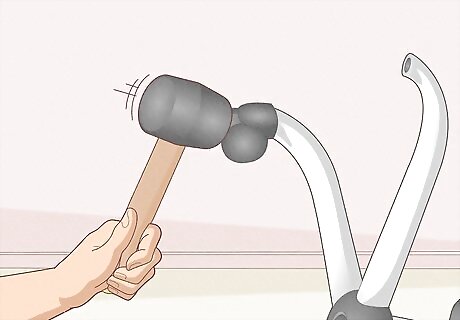

Tap each caster into its chair socket with a rubber mallet. Line up a caster stem with its intended socket and give the caster a good push by hand. If you’re lucky, it will pop into place! If not, grab a rubber mallet and tap lightly on the caster until the stem is fully inserted into the socket. If the caster’s design provides you with room to tap near the base of the stem rather than at the bottom of the wheel, do so. This reduces your chances of deforming or breaking your new caster!

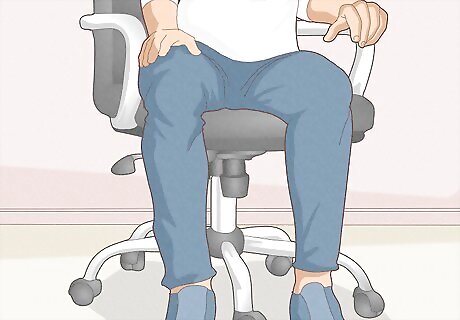

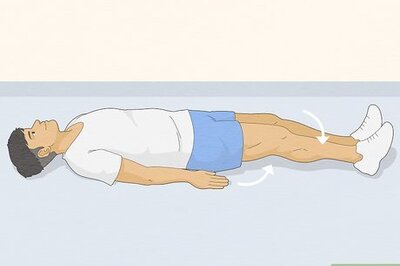

Flip the chair over and test out the new casters. Take a seat on the chair. If it rolls smoothly and evenly and doesn’t lean to one side anymore, you’re all finished! If the chair is still leaning, however, move on to checking the seat plate for damage.

Repairing the Seat Plate

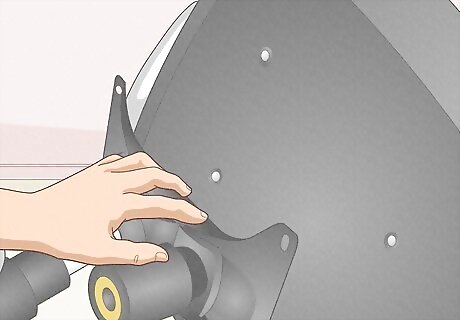

Lay the chair on its side and identify the metal seat plate. The seat plate is normally a piece of painted black steel in a roughly square shape, located on the underside of the chair’s seat. The cylindrical column that serves as the single “leg” of the chair connects to the seat plate, as do any levers used for adjusting the seat height and tilt.

Tighten loose screws, replace missing screws, and test the chair. Most seat plates are secured by 4 screws that drive up into the underside of the seat. If any of the screws are loose, turn clockwise with a screwdriver to tighten them. If any are missing, remove one of the existing screws, use it to find a match, and install the screws securely. Find a matching screw by rummaging through your junk drawer or, better yet, by taking one of the existing screws to a hardware store. Flip the chair upright and sit on it after tightening or replacing any screws. If it still leans, keep searching!

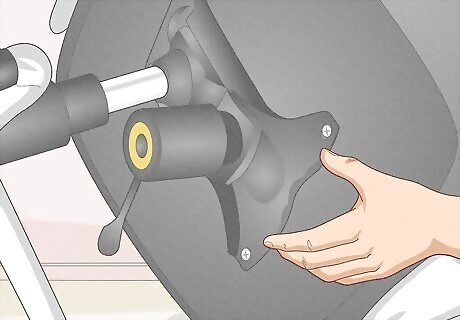

Check the seat plate for bent metal if the chair still leans. Office chair seat plates aren’t perfectly flat, but your plate’s bends, dents, bumps, and holes should be symmetrical and even. If the plate looks deformed, damaged, or worn out, it should be replaced. At this point, you may decide that it’s preferable to just buy a new office chair. However, if it’s an expensive chair, it’s likely more cost-effective to remove and replace the seat plate.

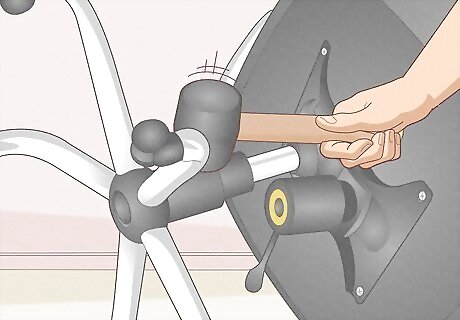

Tap off the chair's "feet" and cylindrical column with a rubber mallet. With the chair tipped on its side, grasp the cylindrical column firmly in one hand. With your other hand, tap the rubber mallet against the seat plate, close to where it connects to the cylinder. A few good raps with the mallet will pop everything below the seat plate—namely, the cylindrical column and the “feet” that spread out from it—free of the seat plate and the upper section of the chair. Smacking the seat plate with the mallet may dent it, which isn’t a problem in this case since you’re replacing the plate. If, however, you’re disassembling the chair and plan to use the same seat plate, strike the underside of the chair right next to the plate instead.

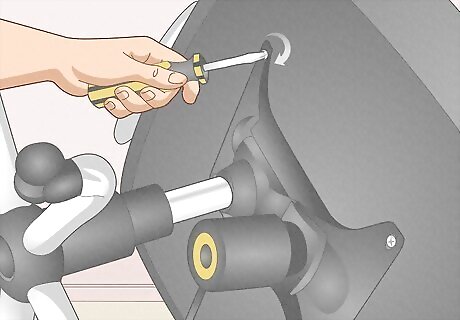

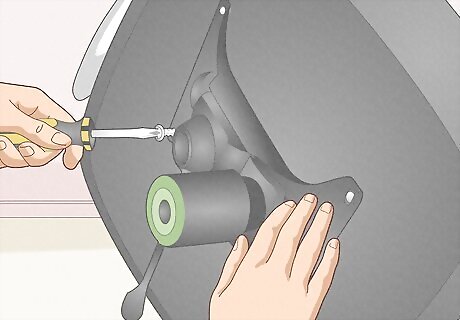

Remove all the screws and pull the seat plate from the chair. As mentioned earlier, most seat plates are held in place with 4 screws. Turn counterclockwise with a screwdriver to remove these screws and pull the seat plate free. Keep the screws as replacements in case you lose any of the screws that come with the new seat plate.

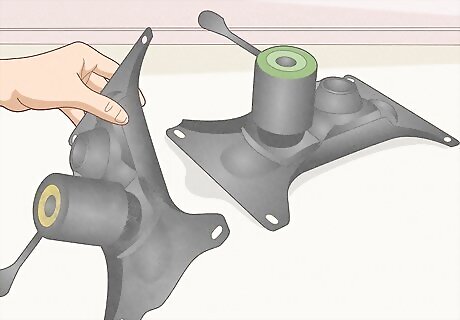

Use the removed seat plate to select a matching replacement. Write down the brand and model number of the chair (if you have this information), bring the seat plate to an office supply store, and purchase an exact replacement. Alternatively, contact the manufacturer and order a matching seat plate. Seat plates are not universal, so a generic replacement is unlikely to fit or function correctly.

Screw the new plate into the underside of the chair. Line up the screw holes in the seat plate with those in the underside of the seat. Insert a screw, turn clockwise with your screwdriver until the screw is firmly in place, and repeat with the other screws.

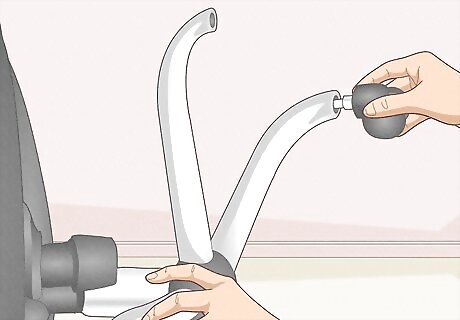

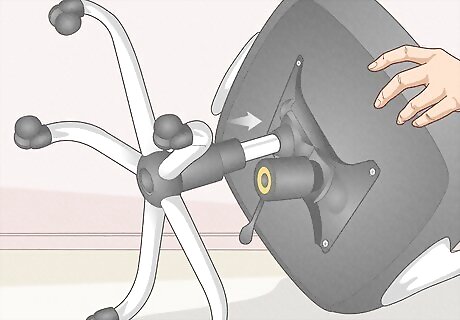

Attach the cylinder and "feet" to the new plate by pressing firmly. Stand the detached lower half of the chair upright on the floor, with the "feet" down and the cylindrical column pointing up. Hold the upper half of the chair over the lower half and line up the socket in the new base with the stem at the top of the column. Press the top half down firmly until you hear the stem pop into place. If you’re having trouble popping the column's stem into place, apply a small amount of spray lubricant (such as WD-40) into the socket, or rub a pea-sized amount of petroleum jelly (like Vaseline) onto the stem. You can now test out the chair. If it no longer leans to the side, congratulations! If, however, you’ve replaced the casters and the seat plate and the chair still leans, strongly consider investing in a new office chair.

Comments

0 comment