views

Oiling Metal Parts

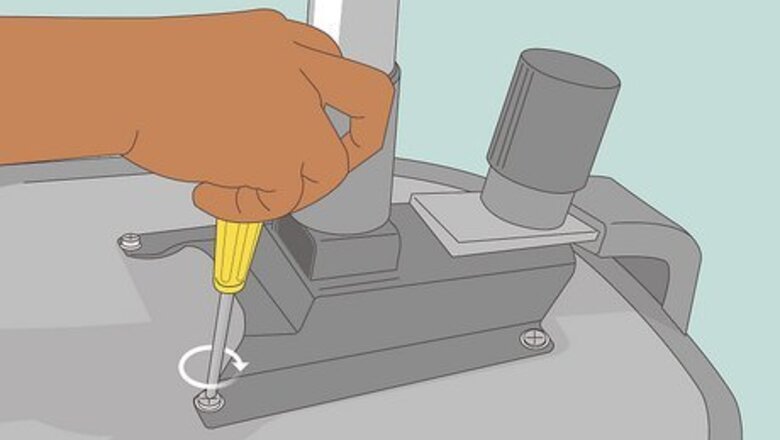

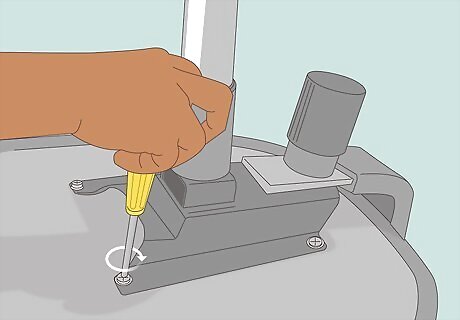

Check the nuts, bolts, and screws. The first thing to do is turn the chair over, and look at all hardware. Get a screwdriver or wrench and tighten any loose ones. Even try to tighten the parts that don't appear loose. Over time, it is easy for screws and bolts to become loose, causing certain chair parts to rub together irregularly and create a squeaky noise.

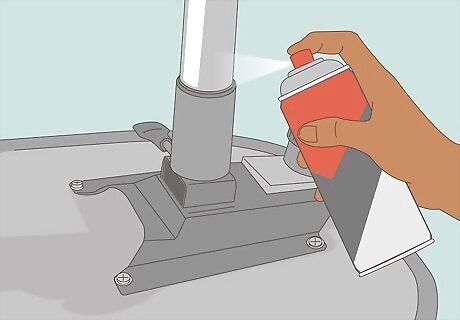

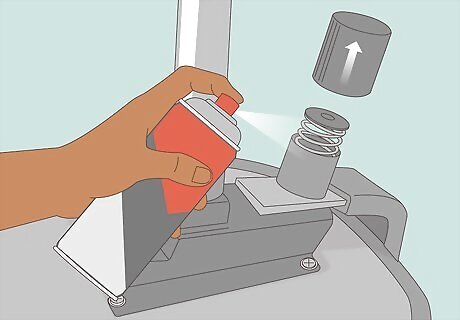

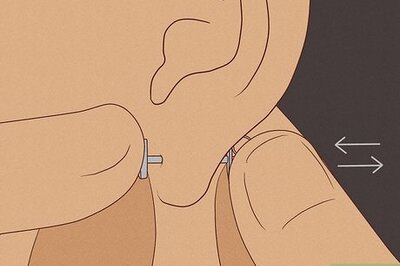

Grease the mechanisms. Apply a lubricating oil on all of the nuts, screws and bolts to help loosen the joints. Simply spray oil directly on the the chair mechanisms, and pat them dry. You can also spray oil on a soft cotton cloth, and rub the oil onto your problem areas to have more control over where the oil goes. Moisture in the air and air conditioners cause rust. Regularly applying oil prevents rust from occurring and building up.

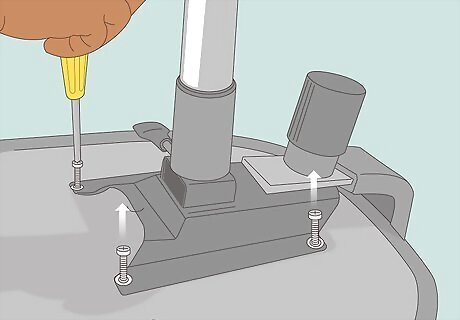

Remove the bolts and screws completely before adding any lubricant. If the chair still squeaks after adding lubricant and tightening all bolts and screws, take them all out, and lubricate them with a light machine oil before putting them back in.

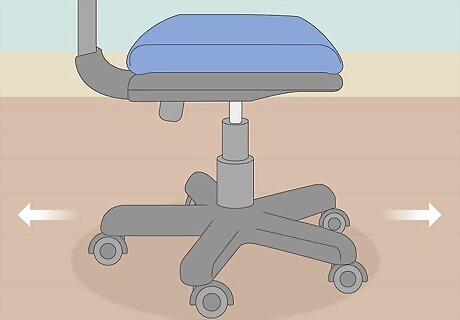

Have a friend sit in the chair as you apply oil. To help you locate the area of the chair that is squeaking, have someone sit in it, and swivel from side to side. By applying weight to the chair to make it squeak, it will allow you to more easily locate the source of the noise to more accurately apply oil. Each time you apply more oil, ask your friend to swivel the chair so you can see if you put oil in the right spot.

Fix the springs in the back of the chair. A chair may only squeak when you lean back, which is usually caused by too much tension where the spring's ends rub on the housing ends. To fix this, apply oil to the seat tension spring located inside the turn-knob housing. Simply loosen the seat tension turn-knob and remove the turn-knob to spray oil inside the housing.

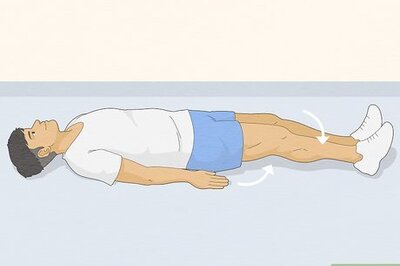

Roll the chair back and forth to check out the wheels. Desk chairs are often on wheels that may move a lot, so it is common for the axles in the wheels to need some silicone spray over time. Turn the chair over and spray the wheels. Then, flip the chair back over, and roll the chair to spread the silicone around the entire wheel.

Sit down gently. Collapsing into a chair will eventually cause it to squeak. Chairs go through a lot of wear and tear, so to keep your chair silent, be cautious when you sit down as to not speed up loosening joints.

Fixing Wooden Chairs

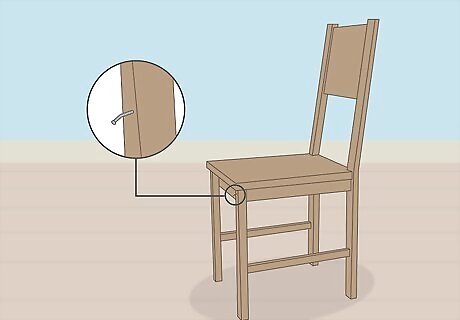

Inspect the wooden chair for loose legs, screw, or nails. Check how loose the chair legs are, as well as the back of the chair, by pushing and pulling them back and forth to see how much movement they have. There should be virtually no movement.

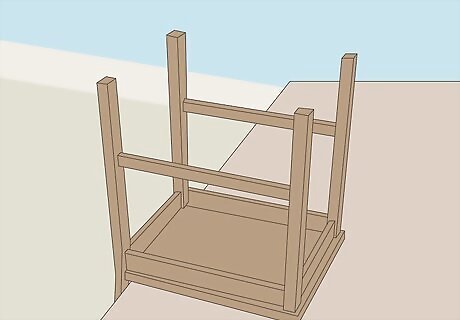

Position the chair you are working on upside down. You can either flip the chair upside down on a table or on another chair so that you can more easily access the problem area. This will also prevent any unwanted pressure on the legs or back of the chair when you are working.

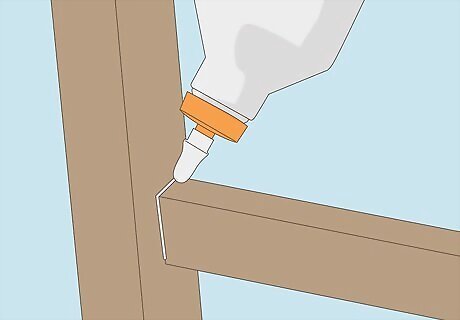

Apply glue to loose joints. There are many types of strong wood glue products you can purchase to stabilize loose leg joints. When you locate a loose joint, push wood glue into the joint and let it dry completely before flipping the chair back over. Wipe away any access glue that comes out of the joint with a wet rag. To create a thicker wood glue consistency, try adding wood filler to the glue. A thicker mixture can better help stabilize wobbly chair legs.

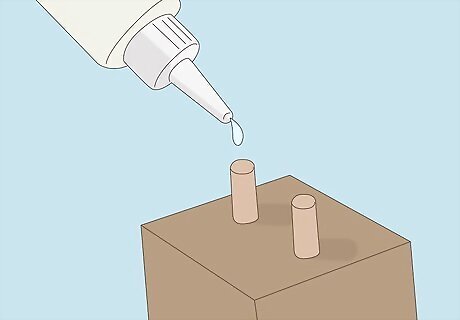

Expand the dowels with wood-swelling liquids. For very loose legs that seem to need more than glue, remove the chair leg completely, and use a wood-swelling liquid. Sometimes, dowels can shrink, causing chair parts to become loose. When you apply a wood-swelling liquid to the dowel, it will allow the dowel to once again become secure in the chair.

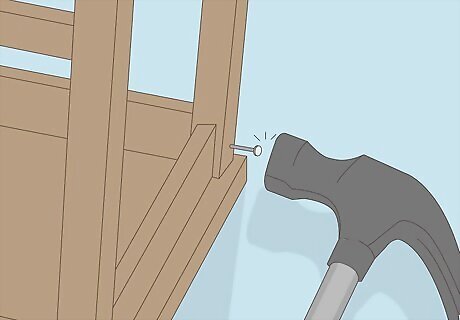

Replace the nails or wooden joint plugs. If the hardware in the chair seem to be loose or no good anymore, you can replace them with new ones. Even if you don't want to remove the existing hardware, you can add reinforcement with more nails or bracket hinges to make the chair sturdy. When putting in more screws, make sure they are long enough to secure the wood, but not long enough to come through the other side of the wood.

Comments

0 comment