views

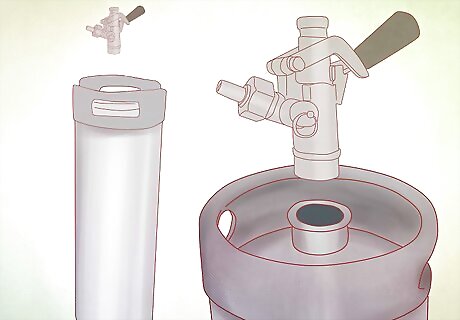

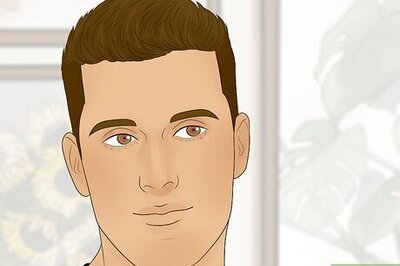

Remove the Empty Keg

Check to make sure your keg is empty. You'll know that your keg is empty if you open the faucet of the tap and either very frothy beer comes out or none does.

Look to see if your keg has a CO2 line. Some kegs will have a CO2 tank that provides pressure inside the keg to help dispense beer. The gas also helps the beer hold its natural carbonation. If the system you're using has a CO2 line, turn it off.

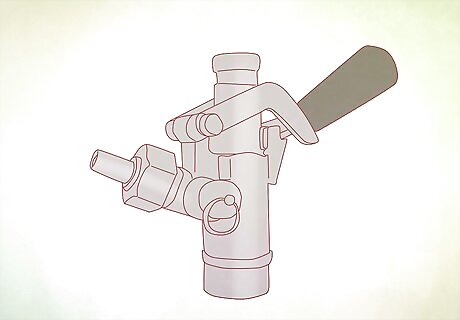

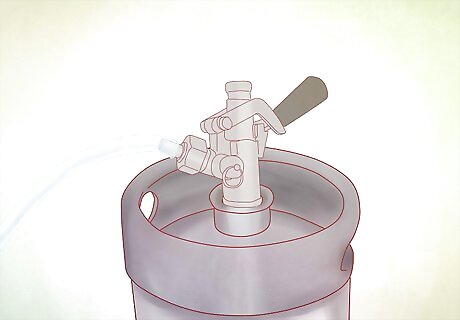

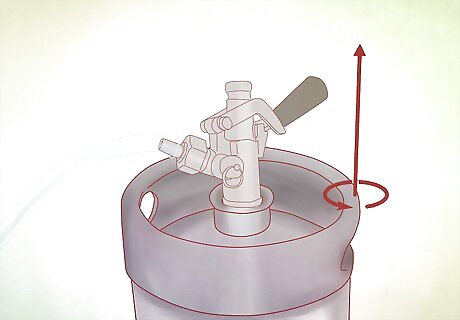

Lift the coupler handle at the base of the tap where it joins the keg. Grasp the coupler and rotate it counter-clockwise until it won't move anymore, usually just a half-turn.

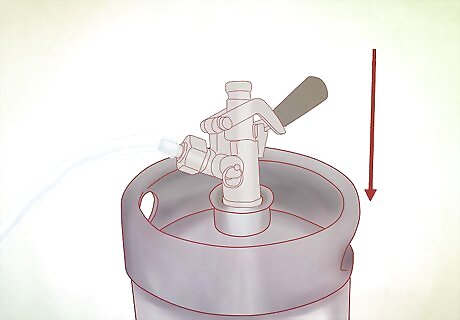

Pull the coupler off the empty keg.

Move the empty keg aside. You can use Powdered Brewery Wash or PBW to clean kegs at home. Mix hot water and PBW in the keg. Scrub with a sponge if needed, or let it sit overnight and rinse the next day.

Connect the New Keg

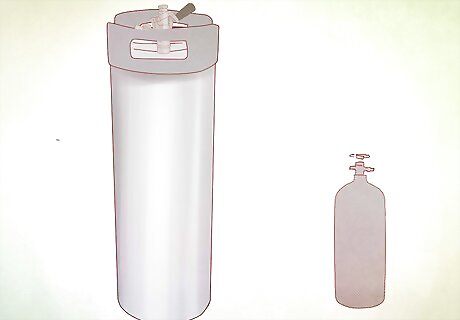

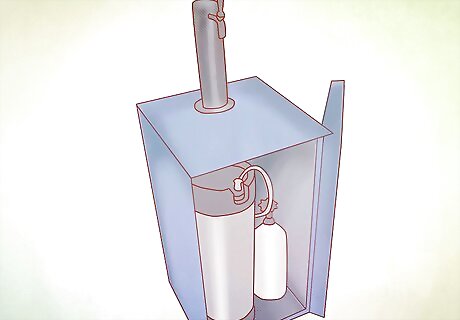

Put the fresh keg in a refrigeration unit or in a tub of ice.

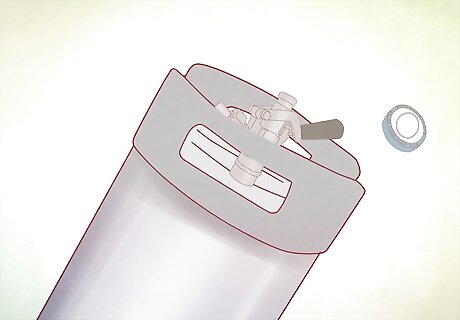

Remove the plastic cap from the top of the keg. The cap will show the brand of the beer and its freshness date.

Ensure that the well of the keg is clean.

Line up the lugs on the base of the tap with the slots in the well of the keg.

Keep the coupler handle raised and fit the tap firmly onto the keg. Twist the tap a half-turn, in a clockwise direction, until it is snug.

Press the coupler handle down to its locked position.

Turn the CO2 canister back on.

Open the faucet fully to expel excess foam that is often built up in freshly tapped kegs.

Make sure the beer flows through the faucet and there are no obvious leaks. If the beer doesn't flow, repeat the process.

Replace the CO2 Canister

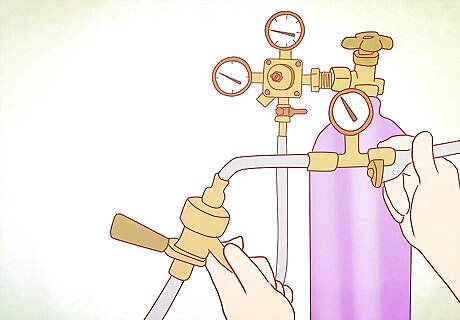

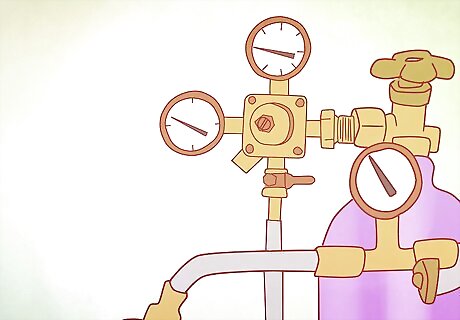

Check the gauge of the CO2 canister to make sure the cylinder is empty. The gauge should read 0. Other signs that you may need to replace your CO2 canister are that no beer flows from the faucet, or the beer is flat.

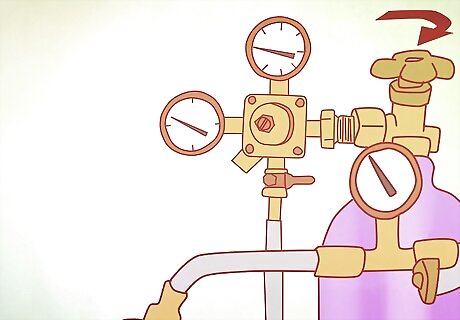

Shut off the valve at the top of the canister by turning it clockwise until it won't go any further.

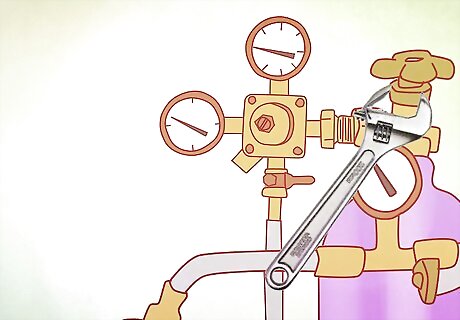

Use a spanner, or specialized wrench, to slowly disconnect the reducing valve from the cylinder to let the remaining gas escape. This will reduce the pressure inside the valve.

Set aside the empty canister.

Install the new CO2 canister. Remove the protective tape from the replacement canister's outlet valve. Connect the new cylinder, tightening it with the spanner. Be sure to install a new plastic washer each time you change your gas canister. Turn the valve back on, twisting it counter-clockwise. Turn it until the hissing from the canister stops and the knob won't turn any further. Make sure the gauge shows pressurization.

Comments

0 comment