views

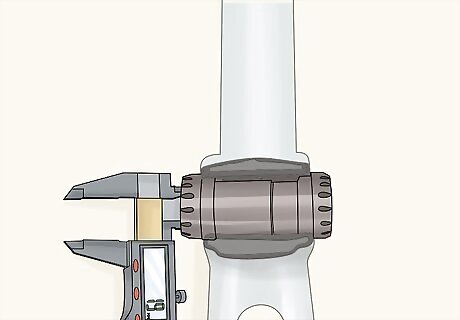

- Look for the bottom bracket’s shell, or the horizontal cylinder near the pedals. Measure its width by sliding the caliper’s jaws around the openings on each side.

- Find the bracket’s length by spreading the calipers around the spindles, or pegs, that stick out of the middle.

- Measure the bracket’s diameter by sliding the caliper’s jaws around either end of the shell.

Removing the Crankshaft

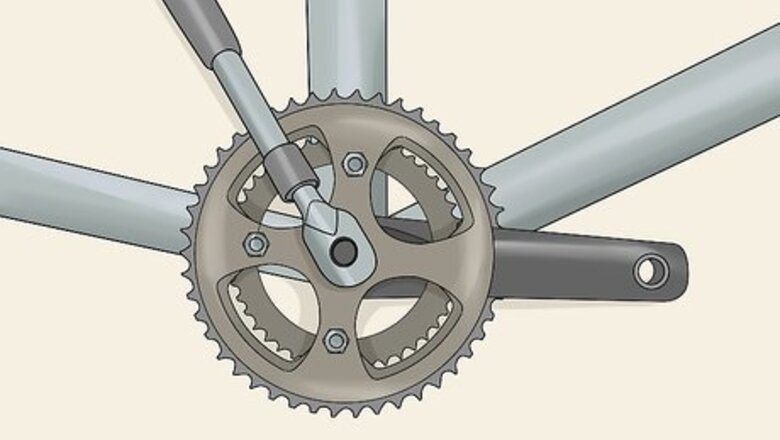

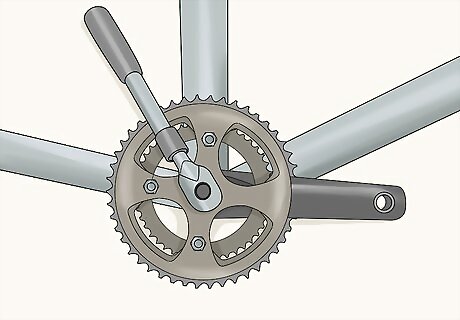

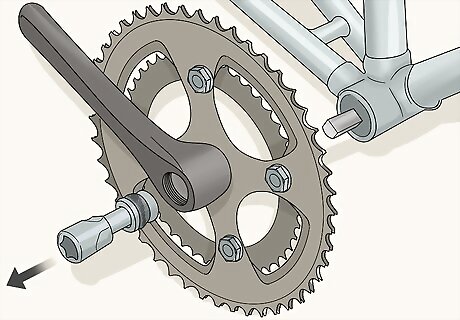

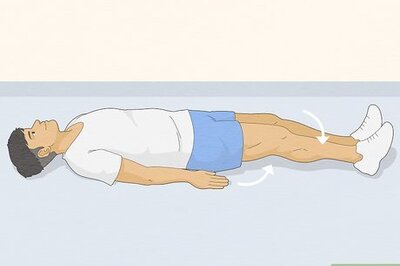

Unscrew the bolt or nut in the middle of the crankshaft. Flip your bike upside down or put it on a bike stand. Inspect the crankshaft, which is the big gear on one side of your pedals, to find how the pedal is connected to the crank. Get a socket wrench or screwdriver that fits the nut or bolt. Unscrew this piece by turning your tool counterclockwise and set it aside.Tip: If the nut or bolt is embedded in the crank wheel, use a crank extractor tool to reach the nut or bolt. Insert it into the opening and wrap it around the nut or bolt. Then, use a wrench to turn the tool counterclockwise. You cannot access or measure a bottom bracket without moving the crankshaft. If you’re measuring a bracket that is not installed on a bike, feel free to skip this section. If there is a piece of plastic sitting on top of this nut or bolt, pop it off with a flathead screwdriver. This is the dust cap. Hold the pedal arm in place while doing this to keep it from turning.

Screw the crank extractor tool into the bolt in the middle of the crankshaft. Under the first nut or bolt, there will be a bolt locking the crankshaft in place. Using the threaded side of your crank extractor tool, slide your crank extractor into the opening in the crankshaft and turn it clockwise to tighten it in the threading, if necessary. On some bikes, the crankshaft won’t have any threading for a crank extractor tool. On these bikes, you can simply push the crank extractor tool into the opening and wrap it around the bolt.

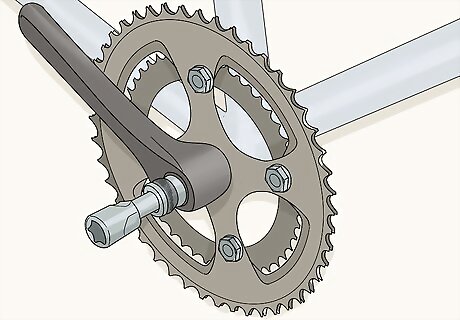

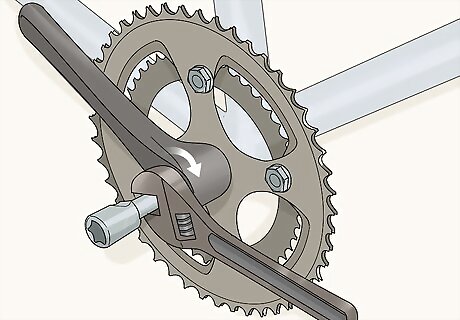

Tighten the socket on the open end of the crank extractor tool. With the tool attached to the nut inside of the crankshaft, turn the socket at the end of the tool clockwise by hand. Once it won’t move any further, use a wrench to turn it. Hold the pedal in place to keep the crankshaft in place. Continue turning the socket until it won’t move any further. The socket should move closer towards the crankshaft as you turn it. If it doesn’t, you’re turning the socket the wrong way. Turning this socket effectively pulls the side of the crankshaft off of the axle.

Slide the crankshaft off of the bottom bracket. Once the pedal in your hand feels loose, simply slide the crank wheel off of the bottom bracket. The crank extractor tool will still be attached to the crankshaft, so turn the socket counterclockwise to remove it. With the crankshaft off, repeat this process on the other side to remove the remaining pedal. If the shaft doesn’t slide off immediately, jiggle the crankshaft a little while pulling it out. Crankshafts can stick a little if they haven’t been removed in a long time.

Measuring the Bracket

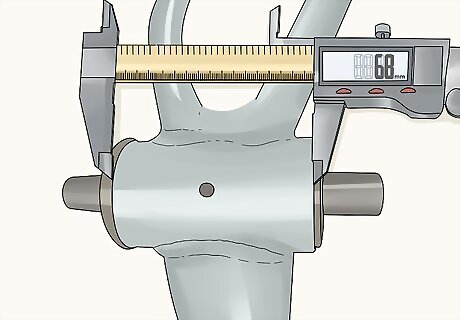

Measure the width of the bracket’s shell using calipers. Flip the bike over or set it on a bike stand if it isn’t already. Inspect the area near your bike’s crankshaft for a horizontal cylinder that connects to your pedals. This is the shell for your bottom bracket. Spread the jaws on your calipers out and slide them around the openings on each side of the shell. Slide the movable jaw on the calipers so that they’re flush against the 2 openings of the shell. Measure your width and write down.Tip: Bottom bracket measurements are kind of confusing. For bracket dimensions, the first number is always the width of the shell. The second number is always the length of the bracket itself from spindle to spindle. Bottom bracket measurements are always taken in millimeters. The most common sizes for the width of the shell are 68 mm and 73 mm. You can use a ruler instead of calipers if you prefer. It’s easier to get a precise measurement with calipers, though. To use your calipers, slide the jaws sticking out of the ruler until they’re flush against 2 surfaces. The number above the hash mark on the movable jaw is your measurement. You can do this with the bracket installed on the bike or measure the bracket separately. You still need to measure a bracket’s bike shell though—not the bracket itself—to determine whether a bracket will fit or not.

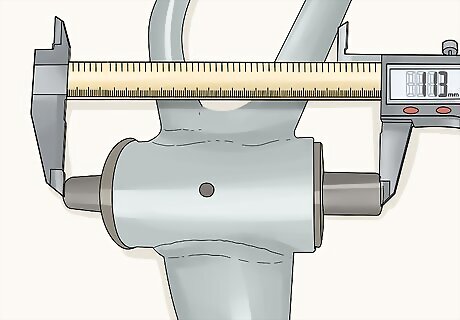

Calculate the length of the bracket from spindle to spindle. Spread the jaws of your calipers out. Wrap them around the pegs that stick out of the middle of the bracket. Close the jaws so that they’re flush with each exterior edge on your pegs. Write this measurement down after the width. This is the overall length of your bottom bracket. The length typically ranges from 113-122 mm. If you’re replacing a bottom bracket, the length of your new bracket must match the length of your old bracket. If you’re replacing the bracket and the pedals though, your bottom bracket’s length must match the required bracket length of your new pedals. The spindles are the little pegs that stick out of the bottom bracket on both sides. You can do this with the bracket installed on the bike, or measure it separately. If your spindles aren’t circular and have flat sides on them, you have a square-tapered bracket. This is the most common fitting type for bottom brackets and is found on basically every bicycle that isn’t vintage or custom-made.

Check the length from edge to edge if you don’t have spindles. Some bottom brackets don’t have spindles. These brackets are called thread-through brackets. For these brackets, use your calipers to measure from the exterior edge to exterior edge. These brackets are commonly found on custom bikes and newer models.

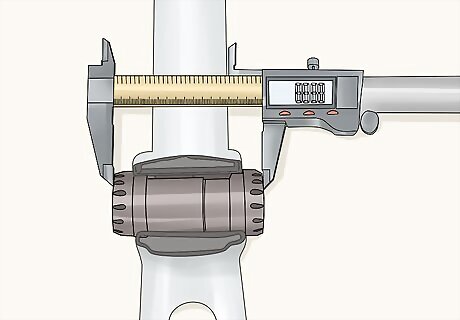

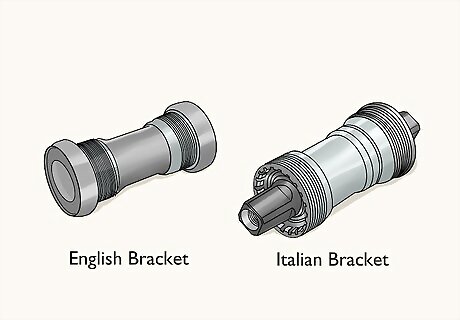

Measure the inner diameter on the side of the bracket’s shell. Spread the jaws on your calipers and wrap them around the side of the shell where the bracket is exposed on either side. Tighten the calipers around the opening to measure the diameter. Write this number down and label it. If the inner shell diameter is 1.37 inches (35 mm), you have an English bracket. This is the most common type of bottom bracket. On a BMX bike, this measurement will typically be either 19 mm or 22 mm. This measurement will be the same on both sides; don’t bother checking the width on each side. The diameter of the bottom bracket itself is irrelevant since some bottom brackets don’t sit flush on the shell. If your shell is not on the bike, you cannot determine this size without reading the instructions for the bracket.

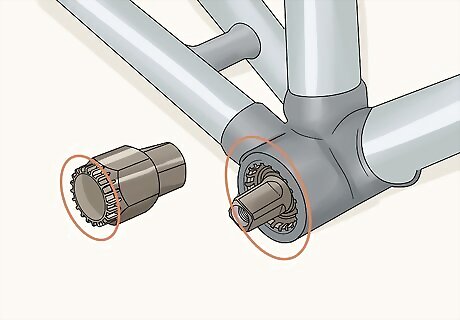

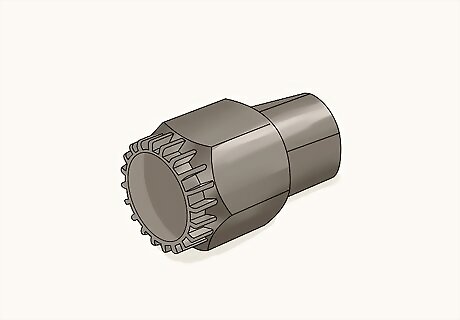

Determine what kind of bracket tool you need to check the threading. To check the threading type, you’ll need to remove the bracket from the bike. Bottom bracket tools come in different sizes based on the cup holding it in place. To determine what size bottom bracket removal tool you need, count the number of notches on the outside rim of the bracket where the cup rests. The number of notches on the bracket will match the number of notches on your bottom bracket.

Remove the bottom bracket using a removal tool or wrench, if necessary. Start on the bracket on the right. Slide the bottom bracket tool over the spindle and wrap a wrench around it. Turn the bracket tool counterclockwise until the cup holding the bracket in place comes out. Repeat this process by turning the bracket tool clockwise on the left. The bottom bracket will slide right out with the cups off. If the right side won’t loosen when you turn counterclockwise, you probably have an Italian bracket. Try turning clockwise instead. If there are no threading whatsoever, you have a press-fit bottom bracket. To remove these brackets, use an old crankshaft or the head of a hammer to gently push the bracket out of the shell. Always start on the drive side of the bracket. The drive side is always on the right of the bike when you’re sitting on it.

Check the threading on the bracket to see what type you have. Some shells have threading for the bottom bracket while others do not. This means that the threading on your bottom bracket must match the threading on the shell. Inspect the direction of the threading on each end of the bracket. If both sides are installed by turning counterclockwise, you have an Italian bottom bracket. If the right-hand side is installed clockwise and the left-hand side is installed counterclockwise, you have an English bracket. If there is no threading in the shell, you have a thread-together bottom bracket and you do not need to worry about threading. The English and Italian brackets are found on the vast majority of bikes. A French bracket refers to an English bracket with smaller threading.

Comments

0 comment