views

Taking the Wheel off of a Push Mower

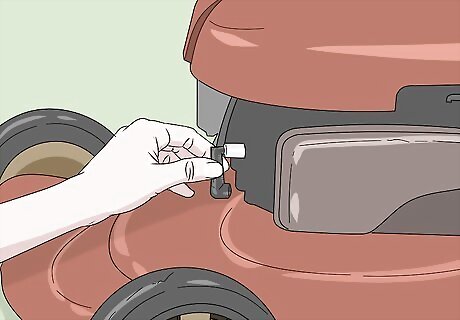

Remove the battery or disconnect the spark plug to cut the power. To avoid electrocuting yourself, cut the power to your mower. Consult your specific model’s instruction manual to see if the battery can be physically removed. If it can’t, look in the front and back of your mower for a rubber tube connected to the motor. This is the spark plug. Pull it out of its connection to manually disconnect the mower’s electrical component. This process isn’t particularly difficult. It should only take 5-10 minutes to remove the wheel. Some batteries have terminals that you’ll need to disconnect while others can be pulled out of the mower without much trouble. On some mowers, you can’t access the battery pack. Every model is different when it comes to batteries. Some spark plugs are screwed into the engine and will need to be turned counterclockwise to remove them. If you have a blade lock on the handle of your power, close the handle together to lock the blades in place. You shouldn’t need to get too close to the blades while you’re doing this though, so don’t worry about it if you don’t have one. Take the battery or spark plugs out during any repairs you do to your lawnmower so you don't get injured.

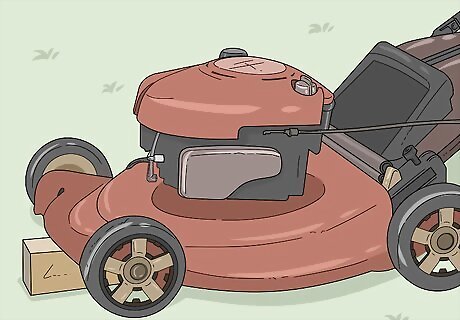

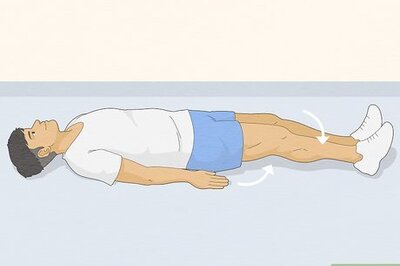

Raise the mower on a brick or block of wood to elevate the wheel. Carefully lift the mower up and slide a brick or block of wood underneath the frame. If you’re going to remove a front wheel, place the brick or block under the front of the mower. If you’re going to remove a back wheel, stick the item under the frame in the back.Tip: If your mower seems a little unstable when you elevate it, use 2 bricks or blocks and place each one on opposite ends of the front or back to stabilize it.

Pry the hubcap off by hand or with a screwdriver if your wheel is covered. If you don’t see a nut in the center of your wheel, you have hubcaps. Pry your hubcap off by hand if there is a lip around the rim of the wheel for you to pull it out. If there isn’t a recessed lip, insert a flathead screwdriver between the cap and the wheel. Apply light pressure to pop the hubcap off. Many push mowers don’t have hubcaps, so don’t worry if you don’t have one. Simply skip this step.

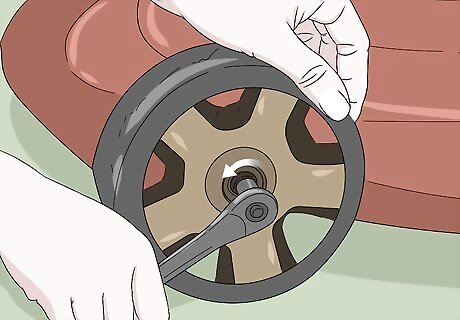

Use a socket wrench to remove the nut in the center of the wheel. Grab a socket wrench that matches the size of the nut in the center of the wheel. Slide the socket over the nut and turn the wrench counterclockwise. Continue turning the wrench counterclockwise until the nut comes off. You may be able to use a standard wrench or channel locks depending on the configuration of your mower.

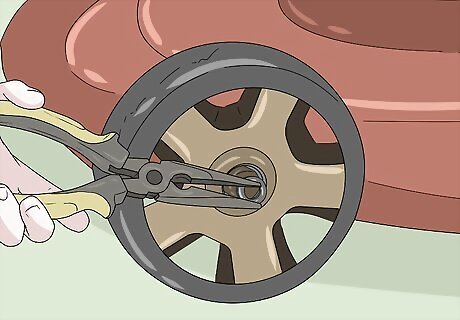

Remove any fasteners or washers by hand or with a pair of pliers. Once you remove the nut, there may be a cotter pin or washer. If you have a cotter pin, grip it with a pair of pliers and pull it off of the axle. If there is a round washer sitting around the center of the wheel, slide it off by hand. A cotter pin looks like 2 parallel lengths of metal with a round section at the top. They resemble bobby pins. Cotter pins and washers are commonly used to protect the wheel from grinding against the nut as you’re pushing it. Many push mowers don’t have cotter pins or washers, though.

Slide the wheel off of the pin holding it in place. With all of your pieces removed, grip the wheel by placing your hands around the rubber on opposite sides. Pull gently, increasing your pressure as needed until the wheel slides off of the pin connecting it to the axle of the mower. You shouldn’t need to apply very much pressure to remove the wheel. If you do need to pull firmly, enlist the help of a friend to brace the body of the mower for you to avoid knocking it over. If you’re going to replace the wheel, use a wheel that is the same brand and model as your original wheel. Install it by completing these steps in reverse order. Reconnect the spark plug or battery before turning the mower back on.

Removing the Wheel on a Riding Mower

Park your mower on a flat, even surface and turn the power off. If you elevate your mower on an uneven surface, it may slide around as you’re trying to remove the wheel. Drive your mower to an even surface and turn the key or press the button to cut the power. If you’re using a mower jack to elevate your lawn mower, park it once you’ve driven over the rigs for your wheel.Tip: You don’t need to remove the battery or spark plug. Once you’ve turned your mower off, the power to the engine is cut and it won’t turn on. This process isn’t hard. Expect to spend 10-15 minutes removing a riding mower’s wheel. If your mower is on the lighter side, you don’t need to use a mower jack to elevate it. If you have a heavy duty mower though, you won’t be able to safely lift it to slide a brace underneath it. Don’t try lifting your mower if it is heavier than 75–100 lb (34–45 kg). To drive over the rigs for a mower jack, set your mower jack out and lower the 2 openings for your tires. All you have to do is ride slowly over the bars at the bottom of each rig until your wheels rest comfortably in each metal frame.

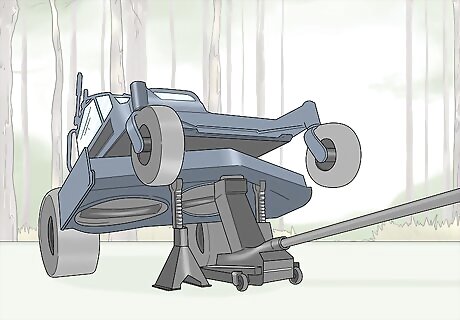

Elevate your mower using a mower jack or block of wood. If you’re using a mower lift, raise the jack’s handle so that it is 90-degrees to the floor and move the tower locking pin at the base to lock the jack’s wheels. Then, lock your mower’s wheels in place if your jack has a locking mechanism for them. Repeatedly press your foot into the pedal at the base of the frame to increase the height of the jack and raise the mower off of the ground. If you have a mower that weighs less than 75–100 lb (34–45 kg), you can slide a brick or large wood block under the side of the frame to lift your mower. Mower jacks are different based on the model and brand. Read your instruction manual carefully to ensure that you’re safely using your mower jack. There are free-standing mower jacks that you can slide under the frame to elevate the mower if you prefer. Some mower jacks lock automatically as you raise them. If your mower does have a wheel lock, it will be a dial near your handle or a strap on each wheel rig. Turn this dial clockwise to tighten the wheel rigs or wrap the strap around each wheel to lock it. If you’re worried about the mower sliding off of the jack, put something heavy behind the wheels in the back to brace them.

Turn the cap in the middle of the wheel counterclockwise to remove it. Grab a pair of thick work gloves and put them on. Then, grip the plastic cap in the middle and twist it counterclockwise. Continue turning the plastic cap until you can remove it from the pin in the middle of the wheel. Most riding mowers do not have hubcaps. If you do have a hubcap, pry it off by pulling it by hand or by using a flathead screwdriver. If this cap is made of metal, you’ll probably need to use a socket wrench or channel locks to loosen this piece.

Use a screwdriver or pliers to pull the cotter pin off of the wheel. With the protective cap removed, you’ll see a cotter pin holding the wheel in place. Slide a screwdriver in between axle’s pin and the cotter pin. Pull away from the center of the wheel to pry the pin off. You can also grip it with pliers and pull it off of the central pin by pulling hard towards you if you prefer. A cotter pin is a type of fastener with 2 parallel lengths of metal with a round shape on top. Bigger cotter pins typically take quite a bit of force to remove. They rely on tension to hold the wheel in place, so you have to pull pretty hard to get a stronger cotter pin off.

Slide the washer off of the center of the wheel. With the cotter pin removed, wrap your hand around the washer in the center of the pin. Pull the washer towards you to slide the washer off of the center of the wheel. These washers are typically quite easy to remove. There’s usually quite a bit space in between the pin and the opening in the middle of the washer.

Pull the wheel off of the center of the pin by sliding it out. Removing a larger riding wheel can be kind of difficult since the column where the wheel sits on the pin is fairly large. Start by wrapping your hands around the back of the wheel and pull it towards you. If it slides right off, you’re done. If it doesn’t, try pushing the wheel back in and then pulling it out again. The wheel may get jammed when you try to yank it out. It has to slide evenly the entire time that you’re removing it to get it off properly. Replace the wheel by completing these steps in the reverse order. Either remove the block underneath the mower or lower your jack before starting your mower back up.

Dealing with Rusty or Stuck Wheels

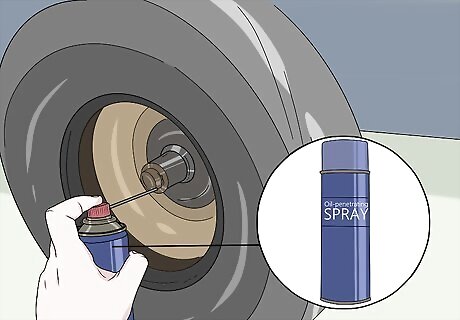

Use an oil-penetrating spray to lubricate the wheel if it’s stuck. If your wheel isn’t sliding off of the pin after you’ve removed the central nut, cotter pin, and washer, there may be some corrosion where the wheel meets the axle’s pin. Push the wheel all the way into its original position and spray some oil lubricant around the pin. Then, pull the wheel back and forth over the pin to spread the oil around. This should make the wheel much easier to remove. Wheels may get stuck due to rust, corrosion, or foreign objects that have worked their way between the pin and the wheel. You can get an oil lubricant at your local construction or home supply store.

Knock a jammed wheel free using a block of wood and a hammer. If the wheel won’t move at all, it may be completely jammed on the pin. Grab a thick block of wood and a hammer. Hold the block of wood anywhere against the front of your wheel between the center and the edge. Then, hold the block in place with your nondominant hand and strike the block with your hammer. Use your hand to turn the wheel 1/4 of the way and repeat this process until the wheel straightens out and you can remove it. This forces the wheel loose by knocking it back into alignment with the pin. This may also straighten out any bent lengths of metal inside the frame of your wheel. You can use a maul or heavy wrench instead of a hammer if you prefer.

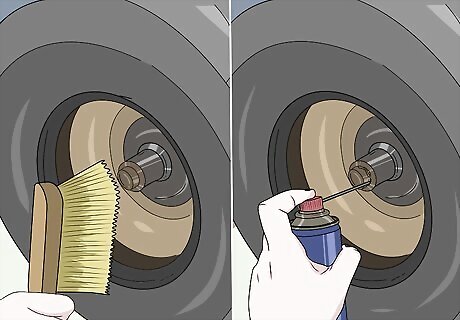

Scrape rusty nuts before lubricating them and removing them. If the nut in the center of the wheel is rusted out, use a stiff-bristled brush to scrape as much rust off of the nut as possible. Then, lubricate the nut with an oil-penetrating spray. Repeat this process as needed before turning the rusted nut counterclockwise off of the wheel.Tip: Even if your nut is thoroughly rusted through, you should be able to get it off. Mower wheels aren’t particularly strong and they’re designed to be easily removed.

Comments

0 comment