views

Removing the Bearings

Gather the necessary materials. To make this job go faster and get you back on your board sooner, having the right tools at the ready is a must. The necessary items are listed below under Things You'll Need. In particular you'll need pliers/screwdriver, a socket wrench or ratchet and a skate tool (or T-tool). You'll also need a bearing pole.

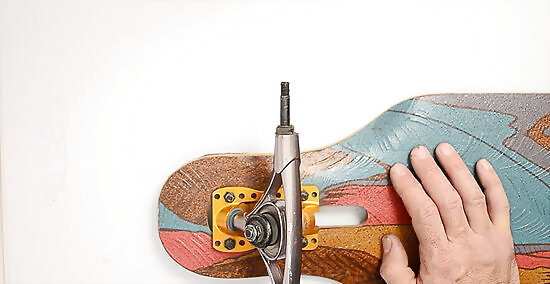

Remove the skateboard's wheels. You can do this easily by using a socket wrench, ratchet or skate tool to loosen the nuts holding the wheels in place. You may need to hold your board steady and apply firm pressure to break the bolts loose.

Store the removed parts in a safe place. It's easy to lose or misplace a necessary nut, washer, or some other part when you're working on your board. To prevent this, consider putting the parts you're not working with inside a plastic bag. For each wheel removed, you should have a bolt and one to two bearing washers.

Free the bearings from the wheels. The bearing will occupy the core of the wheel and will be circular in shape. After removing the wheels, you can gently pry out the bearings with a screwdriver, or pull these out carefully with needle-nose pliers. If you don't have a tool available, put the wheel on the truck like you're attaching it, but make sure only one bearing (out of the two for that wheel) goes on the truck. Then wedge the bearing out, using the truck for leverage. Some boards have an additional spacer between bearings called a speed ring. You should remove this after freeing the first bearing. If you don't have a bearing puller, you can use a thick metal rod (thin enough to fit through the opening of the bearing where the axle usually goes through), touch the bearing on the opposite side when inserted the metal rod, and gently tap the rod with a hammer. However, doing this may damage the bearings, so you must be very careful.

Cleaning the Bearings

Clean off major dirt and grime. Be sure to do so gently, to avoid grinding dirt into the bearings. Gently rub the bearings with a dry rag or paper towel to eliminate all obvious dirt. If the grime is especially bad, apply a moderate amount of solvent to the rag or paper towel, to help cut through the gunk.

Prepare a cleansing solution. Using a clean bucket or bowl, fill it with the acetone or a grease cleaning solvent. Mineral spirits or rubbing alcohol work well, are relatively inexpensive, and are less harsh than some cleaners. Fill the bucket or bowl just enough to submerge the bearings. If you decide to use acetone, please remember to wear gloves, as this solvent is quite strong. Note that not every boarder recommends the use of acetone, and you may choose to use a milder solvent instead. Wear gloves when handling acetone! If you use a milder solvent, like mineral spirits, you may have to wait a little longer for the bearings to become fully clean.

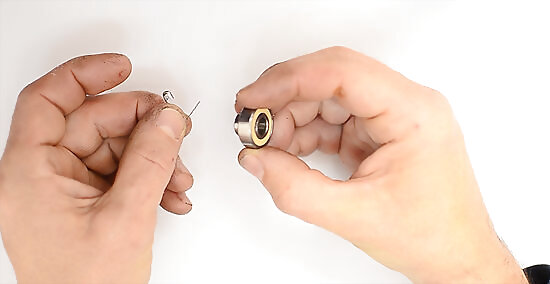

Pop off the bearing shield caps. Take the bearings in hand and using a small, thin object, like pin, paperclip, or the point of an X-acto knife, pry the rubber shield from the bearing. These caps are usually black or red. After removing the cap, you should see tiny metal balls. If you have difficulty doing this, try to insert the pointed object between the rubber cap and bearing housing, then gently pry until the cap comes free.

Soak the bearings in the solvent. Now the bearings are ready to be put in the cleaning solution. Swirl the bearings around in the solvent for about five minutes, then let the bearings sit in the liquid for about ten minutes. If the grease solvent has considerably darkened, you may need to carefully drain the solvent and add some more to the bucket. Do this as many times as necessary until the bearings look clean.

Remove and dry the bearings. Before removing the bearings, prepare a level, safe place where these can dry. Lay down paper towel or a rag, remove the bearings, and allow enough time to pass until completely dry.

Greasing and Reassembling the Bearings

Accelerate the drying. Let the bearings dry for about 10 minutes. You can speed this process by using canned air to spin the bearing. Aim the canned air into the open side of the bearing and spray. If it doesn't move, use your finger to spin the bearing and spray the air while the bearing is already spinning.

Apply the lubricant. It is best to use lubricant specifically intended for skateboard bearings. You should only need two or three drops of lubricant in each bearing. After applying the lubricant, spin the bearing to distribute throughout the bearing. Do not use: Cooking oil, motor oil, or anything that might gunk up the bearings or create stickiness. WD-40 is also not recommended, as it lasts a short time, junks up the bearings, and can dry bearings out, counteracting the lubricant. Instead, use a Teflon-based rather than silicone-based lubricant.

Replace the bearing shields. The shields should pop into place without much difficulty, but take care to make sure the seal between the bearing shield and bearing is complete. Check to ensure that there are no gaps.

Reinsert the bearings. Replace the bearings into the wheels by pushing each firmly with your finger into the wheel as far as you are able. Drive the bearings home by pushing the wheel down onto a skateboard truck as hard as you can. If your board came equipped with the bearing spacer (speed ring), do not forget to put this between bearings just as you found it.

Refasten the wheels. Now that the bearings are in the wheels as far as possible, reattach the wheels back to the trucks. Remember to put one washer on each side of the wheel. Then tighten the bolt until the wheels are firm, but not stiff. The wheels should jiggle slightly after reattaching.

Make sure the wheels are fastened correctly. Tightening a nut too much can hamper the wheel's ability to spin. Test each wheel by hand, spinning each to make sure every one moves freely. If a wheel doesn't spin or is hard to spin, loosen the bolt that holds the wheel on the truck slightly.

Comments

0 comment