views

Hyundai Motor Company and Kia Corporation unveiled the Active Air Skirt (AAS) technology recently, which reduces aerodynamic resistance generated during high-speed driving, thereby increasing the driving range and stability of electric vehicles (EVs).

During high-speed driving, AAS regulates the airflow entering through the lower section of the bumper and efficiently manages the turbulence created around the wheels of the vehicle by functioning differently based on the vehicle’s speed.

Hyundai Motor and Kia revealed that after testing, they installed AAS in the Genesis GV60 to reduce the drag coefficient (Cd) by 0.008, improving drag by 2.8 per cent. This number can anticipate an extra 6 km of range improvement. After completing durability and performance testing, Hyundai Motor and Kia intend to explore mass production. They have applied for related patents in the United States and South Korea, as per the press release.

The race to achieve a longer driving range on a single charge has intensified in the EV era, which highlights the significance of the vehicle-aerodynamics interaction. Moreover, driving stability, wind noise and power performance are all significantly impacted by aerodynamic performance.

As a result, manufacturers are looking into different ways to lower the coefficient of drag (Cd), or the air resistance coefficient acting against the direction of the vehicle’s motion.

Active Air Skirt (AAS) Technology: Details Here

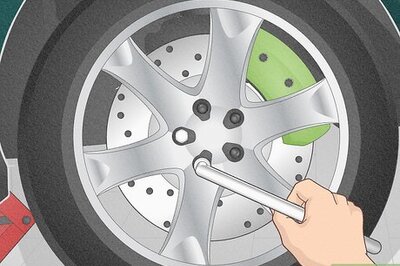

AAS is installed between the front bumper and the front wheels of the vehicle and is hidden during normal operation; however, it operates at speeds greater than 80 km/h when the aerodynamic resistance exceeds the rolling resistance and is then stored at 70 km/h. The difference in deployment and storage speeds is intended to prevent frequent operation within specific speed ranges.

Also, the fact that AAS only covers the front part of the tyres rather than the entire front is due to the characteristics of Hyundai Motor Group’s E-GMP platform for EVs. Because the platform floor is flat, covering only the tyre is more effective in improving aerodynamic performance. This also increases the vehicle’s downforce, which improves traction and high-speed stability.

Additionally, AAS is capable of operating at speeds exceeding 200 km/h. This was made possible by applying rubber material to the lower part, which reduces the risk of external objects splashing and causing damage while driving at high speeds while also ensuring durability.

Meanwhile, Hyundai Motor and Kia are using various technologies on their vehicles to achieve competitive drag coefficients, including rear spoilers, active air flaps, wheel air curtains, wheel gap reducers, and separation traps. The Hyundai IONIQ 6, which incorporates these technologies, has a global leading Cd of 0.21.

Comments

0 comment